How to Install Your Chemical Storage Tank Safely

If you’ve recently purchased a new polyethylene chemical storage tank or are planning on purchasing a poly tank, there are several ways to protect your storage solution from the start.

To help ensure safe, effective operation and a long tank life, we’ve developed a few simple guidelines to help you prepare to install your polyethylene storage tank.

Your Guide to Proper Poly Tank Installation

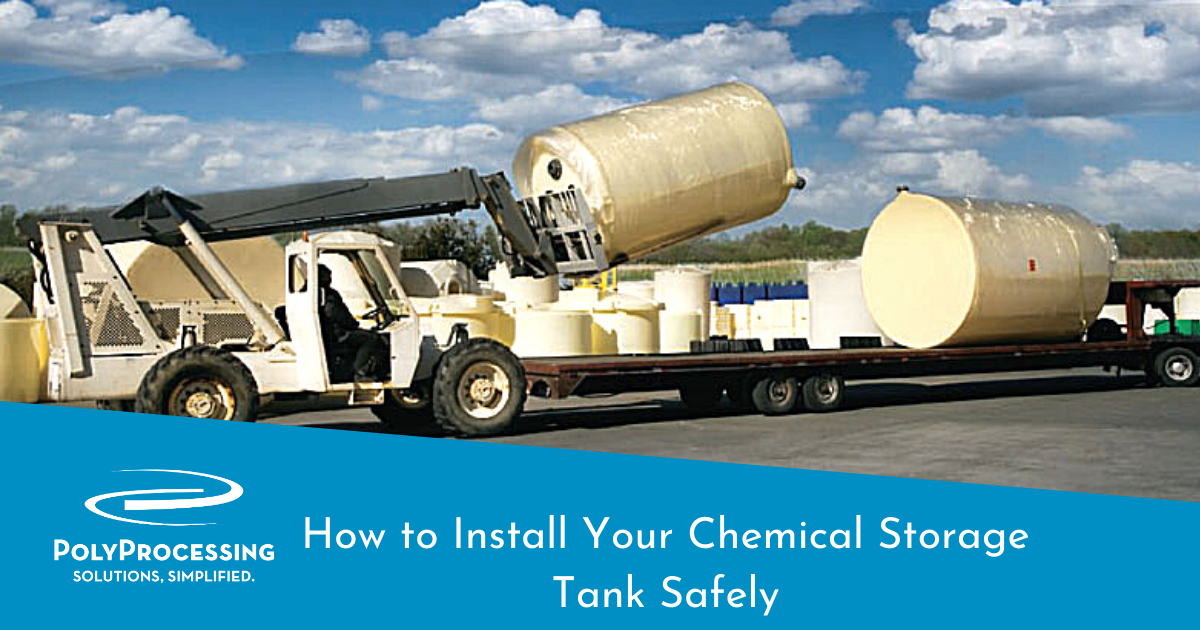

1. Have the right equipment

Have a crane, boom truck or forklift with extended forks, available to move the tank from the delivery truck to its location. Using equipment that isn’t designed to lift or move a sizable tank can cause damage to the equipment and to the tank itself. This can be a costly mistake that is important to avoid.

2. Choose a safe location

Ideally, your chemical storage tank should be installed in the final location where stored chemicals are available for use in your application. However, if the permanent tank location isn’t ready for installation, identify a safe, temporary location to place the tank until the site is ready for use. Make sure the location is out of way of operations and traffic from equipment that could damage the tank before installation.

3. Prepare a smooth, level foundation

The chemical tank must be installed on a smooth and level foundation. Not having a level tank surface causes uneven stress on a tank and can eventually lead to problems down the road.

4. Use flexible plumbing

Polyethylene tanks regularly shift or flex during operation. For example, when a tank is being filled, expansion takes place on the lower sidewall. Natural events, like earthquakes, could shake or move the tank, applying stress to connection points. Engineer your tank fittings to accommodate such occurrences to avoid unnecessary stress on the fittings. Poly Processing has detailed information regarding acceptable expansion joints in our Installation Guide. Neglecting this step could lead to leaking fittings that will require replacement, as well as damage to other equipment or put employees in danger.

5. Tank plumbing supports and venting

When designing your chemical storage system, Poly Processing’s tank specialists will help to ensure you have the proper tank plumbing supports and tank venting system in place. If you’re unsure whether or not a pipe needs support or if your tank plumbing is stable enough, we can help you move forward with confidence. Getting the right structural supports for your tank fittings and tank plumbing in place from the beginning is crucial to mitigating risk of plumbing failure.

6. Ensure compatibility of fittings

Check to make sure all tank fittings are proper and are well-suited for both the type of tank as well as the chemical you’re storing. Chemicals will react to different materials in different ways. For example, while the chemical you’re storing might be compatible with the polyethylene of the tank, it may corrode the steel used in the bolts of untested fittings, causing leaks.

7. Educate and protect employees

Attach the appropriate and required warning labels to the chemical storage tanks and surrounding areas. Make sure all employees are trained in safe operations of the chemical storage tank and chemical handling. When you take proper safety precautions at the onset of a tank installation, you can set the stage for proper chemical storage and safer operations.

Additional Polyethylene Tank Installation Resources

To prevent issues with your polyethylene storage tank and ensure safe operations, follow proper tank installation standards as outlined in the Poly Processing O&M Manual. This installation and operation guide contains very useful information for off-loading your new tank and specific fittings assembly instructions.

After the tank is properly installed, follow the tank start-up checklist and review the safety tips included in the guide.

Poly Processing Company also offers tank start up services. A factory trained Poly Processing Service Technician will visit the site and help make sure things are set up and installed properly prior to chemicals being introduced for the first time.

If you have any questions about how to prepare for a tank installation, contact a Poly Processing Field Service Team Member.

- November 9, 2020

- Topics: Installation and Service, Value Added

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Protect Your Facility and Your Bottom Line with a Chemical Leak Detection System

- PPC Installation, Operation, and Maintenance Manual: Ensure Tank Longevity

- How To Use The Chemical Resistance Guide

- Better and Safer Alternatives to Downpipes

- Crosslinked Polyethylene Vs. Fiberglass Reinforced Plastic Tanks

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package