Secondary containment systems are recommended safeguards that can prevent costly damage to equipment and risk to employees in the event of a leak or failure of the primary storage vessel.

There are several options with varying costs available to tank owners. In this guide, we'll cover different types available and what you need to consider when looking for the right solution for your company.

Inside You'll Find:

Curious what's inside? Check out the guide's content below before taking it with you.

What Is Secondary Containment?

On January 9, 2014, a chemical spill fouled the water supply for thousands of West Virginians. A hazardous chemical used for washing coal called 4-methylcyclohexane methanol, or “crude MCHM,” leaked from an industrial facility into the Elk River near Charleston, West Virginia. The incident could have been prevented if a proper secondary containment system had been in place.

Secondary containment is an important safeguard that helps plant operators mitigate the risks associated with chemical spills. The system consists of a primary container, which is surrounded by a secondary container or wall. Between the two is an interstitial space. If the primary container fails and a chemical leaks, the secondary system prevents the chemical from spilling out beyond the unit.

In the event of a leak or failure of the primary storage vessel, secondary containment systems can prevent costly damage to equipment and physical risk to employees and nearby residents.

In this guide, we’ll walk you through the different systems available, and help you understand which one is the best choice for your containment needs.

Industry Use

Secondary containment is an essential system for any company that needs to contain harmful chemicals or hazardous waste. Here is a sampling of the most common industries that use these systems.

Municipal Water and Wastewater Treatment Plants

Most of the chemicals used in water treatment pose risks of contamination or harm to humans in the event of leaks or spills. Secondary containment is a must.

Hazardous chemicals such as sodium hypochlorite, citric acid, and sodium hydroxide are commonly used to clean and flush the membrane materials used for filtration. Sodium hypochlorite is a bleach commonly used to disinfect water. Often,

While we treat our water with small amounts of fluoride in some geographical areas,

Industrial Facilities

Three of the most challenging industries for storing chemicals are the plating, mining, and high-tech industries. They use aggressive chemicals and require chemical storage solutions that can handle highly corrosive compounds.

- Plating: The plating industry needs to safely store harsh chemicals used in many different plating processes, including Zinc Sulfate, Potassium Chloride, Boric Acid, etc.

- Mining: When mining companies leach copper from oxide ore, they often use concentrated sulfuric acid. This highly exothermic acid presents serious storage challenges because it’s an extremely heavy chemical that will test the mechanical integrity of any tank system.

- High-Tech: In the high-tech industry, chemicals vary from manufacturer to manufacturer—and are frequently proprietary. Many of the solutions are high-purity or ultra-high-purity chemicals that are used for applications like circuit board manufacturing.

De-icing

Manufacturers of de-icing fluids use several harmful chemicals, including magnesium chloride, propylene glycol, and ethylene glycol. Whichever chemical is used during the deicing process, it is important to store it safely so that it is properly contained according to environmental regulations.

These and other industries rely on their secondary containment structures to protect their workers, the environment, and their investments. But many businesses make uninformed decisions about what kind of containment system is the best option, and they create more work for themselves—and lose more revenue—as a result.

Secondary Containment Solutions

Concrete secondary containment systems are the most well-known option, but there are other types of systems that may be a smarter choice for your company. Here’s an introduction to three basic types of units available to your business.

1. Concrete Containment

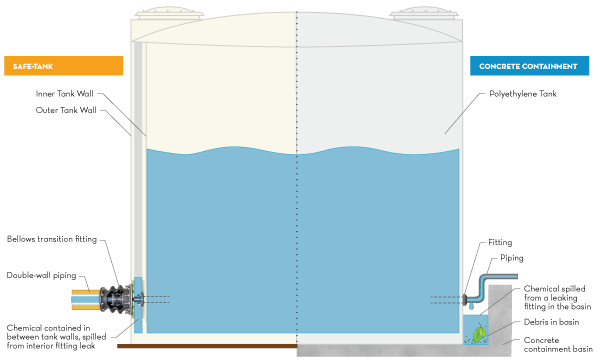

Concrete containment structures are the traditional solutions for secondary containment. Generally speaking, they consist of a poured concrete foundation that is combined with vertical concrete walls. These walls are usually reinforced with rebar. After the concrete is poured, its interior is usually coated with a substance that prevents spilled chemicals from eating away at the concrete. Neglecting to protect the walls can cause serious damage to the containment structure.

The containment area is open, allowing rainwater and debris to collect in the overspill space. Often, the containment walls are only a few feet high—workers can potentially come in contact with a leaked chemical.

2. Polyethylene Containment Basin

To reduce the costs associated with concrete containment, you may want to consider a polyethylene containment basin. In this solution, a polyethylene tank is placed inside of a polyethylene open-top tank. The open-top tank eliminates many of the primary costs and maintenance costs that come with concrete units. They can also be stored indoors to prevent contamination from rainwater and debris.

However, the basin solution has its disadvantages as well: workers can still be exposed to spilled chemicals, and not every facility has the space to house the units indoors. This means spilled chemicals in most cases must be disposed of and replaced.

3. SAFE-Tank®

Poly Processing’s SAFE-Tank system is a “tank-within-a-tank” that keeps contaminants from entering the interstitial area. These tanks provide enclosed secondary containment to prevent damaged equipment or property, lost chemicals, and injured to employees in the event of a spill.

In the event of a spill, the SAFE-Tank system’s all-in-one design features a protected containment area that safely isolates reactive chemicals, protects employees from harm, and protects you from environmental remediation—all within the footprint of a standard vertical tank.

If your primary tank develops a leak, the liquid is captured by the outer sealed secondary tank and the system essentially becomes a single-wall tank until it can be repaired. This allows you to continue using the chemical within the primary tank until the tank system can be emptied, inspected, and repaired if necessary.

SAFE-Tanks are ideal for chemicals that have dangerous exothermic reactions to water that could occur in a traditional containment that will capture rain or wash water.

Considerations

There are many factors you need to consider when deciding what is the right Secondary Containment Solution for your company.

Cost

There are several components of a chemical storage system and it is important to factor in the costs of each component. When it comes to secondary containment, you must consider costs of the primary tank, the secondary tank, any coating on the containment structure, maintenance costs, and the potential cost of purchasing new chemicals in the event of a spill. When you look at it

The SAFE-Tank itself costs less than a primary tank with a concrete system, and it is maintenance-free. Once you’ve made the purchase, you’re done. There are no additional man-hour costs or maintenance investments to drain your bottom line.

On the other hand, there are several costs involved with concrete containment structures. Concrete can cost up to $9 per gallon or more, depending on the type of coating that is used. Because a secondary containment tank must be able to hold 110% to 120% of the primary tank, the secondary containment for a 1000-gallon tank could cost upwards of $9,000 or more. That doesn’t include the cost of the primary tank.

While an open-top tank system is less expensive than concrete, you should expect a total loss of the chemical. As with concrete systems, the entire chemical supply can become contaminated by rainwater or debris in the event of a chemical spill or leak.

Properly disposing of leaked or contaminated chemicals can involve renting a tanker truck, which can range from $5,000 to $10,000 or more. In addition to this cost, replacing the chemicals can cost from $1 to $10 per gallon or more. But the SAFE-Tank’s enclosed system allows leaked chemicals to be fully used which eliminates unplanned costly expenses.

Space

It's also important to consider the footprint of the solution you are considering. For instance, concrete berms can require a lot of space because they must provide a capacity of 110-120 percent of the primary tank. On the other hand, you could reduce the footprint of your containment system by using a SAFE-Tank because it takes up less space around the primary tank.

Since it’s built from high-density cross-linked polyethylene that can hold the chemical, there is no need to designate a large area for a concrete containment structure. Only one tank pad is needed. And since any spills are self-contained, you can also store acids and bases right next to each other.

Safety

When you're storing dangerous chemicals, it’s your top priority to make every effort to prevent leaks and spills that could cause harm to employees, the general public, and property. All secondary containment options will deliver some peace of mind but the SAFE-Tank’s completely encased sidewalls provide superior safety protection. Not only is a spilled chemical protected from rainwater and debris, but workers are protected from splashing and spurting if the leak occurs.

You also won't have to worry about leak detector false positives due to environmental moisture— rainwater can’t enter the interstitial space to trip the detectors.

What Is The Right Solution?

Each secondary containment system has its advantages and disadvantages. Whichever option you choose, it’s important to make the right choice for your operation’s needs. Selecting the wrong system result in unplanned expenses, more maintenance, or more operational frustrations.

How can we help?

If you have any questions or would like to speak to a chemical storage expert, please submit a message using the form to the right. Our goal is to make sure you have all of the information you need to build a safe storage system for your specific application.