Bellows Transition Fitting Installation Video Guide

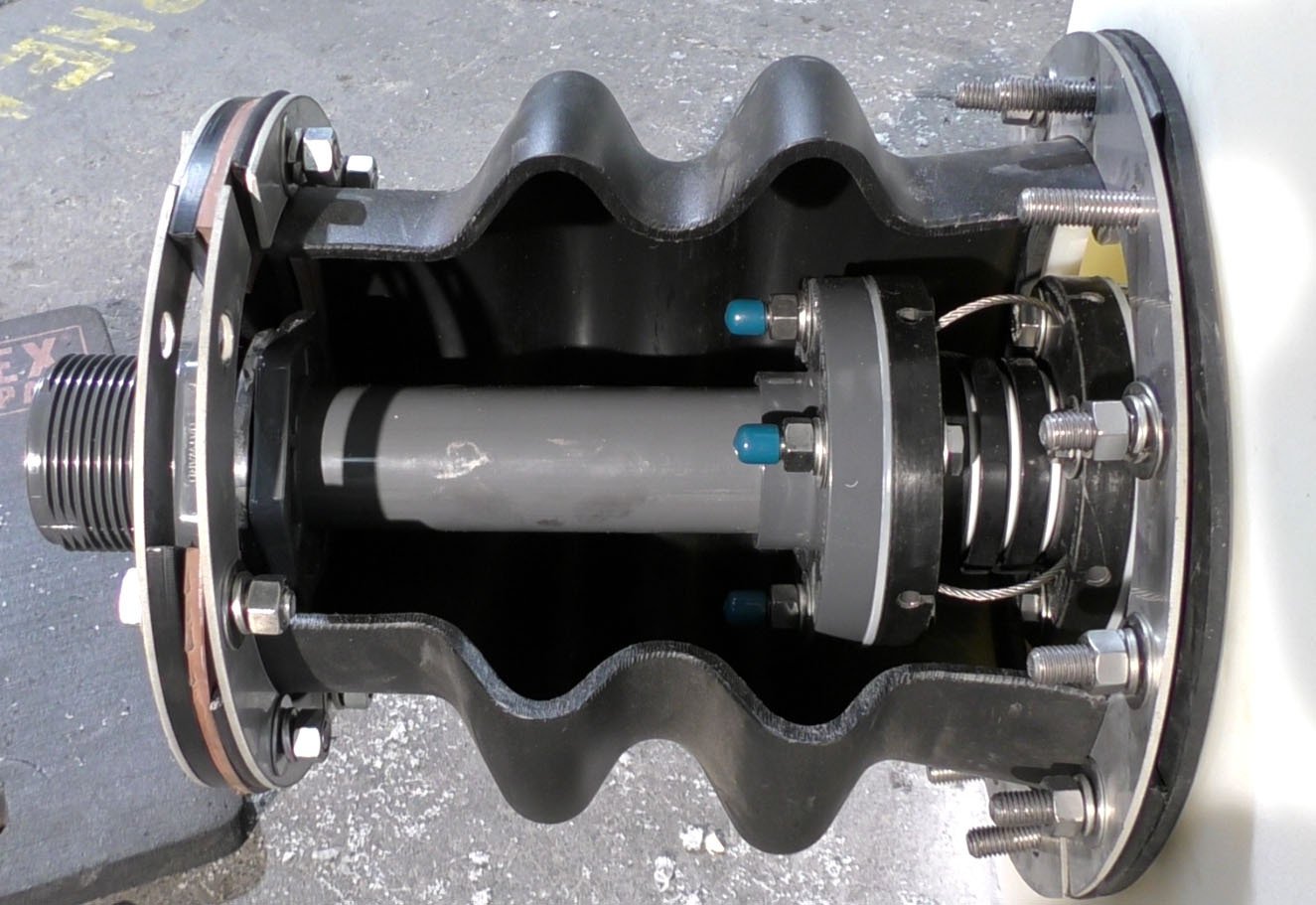

The Bellows Transition Fitting provides secure yet flexible, fully contained SAFE-Tank® bottom discharge. An expansion joint is incorporated to allow the tank to expand and contract freely during loading and unloading. This fitting virtually eliminates damage from piping vibrations caused by pumps.

All of the pressure-tested internal components of the fitting come to you pre-assembled and ready to install. Please follow the two videos that discuss how to install the SAFE-Tank and the Bellows Transition Fitting. Below are the links to the two videos:

Installing The SAFE-Tank

Installing The Bellows Transition Fitting

If you have any questions about how to install a Bellows Transition Fitting, please contact the Poly Processing Field Service Department.

- December 23, 2013

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package