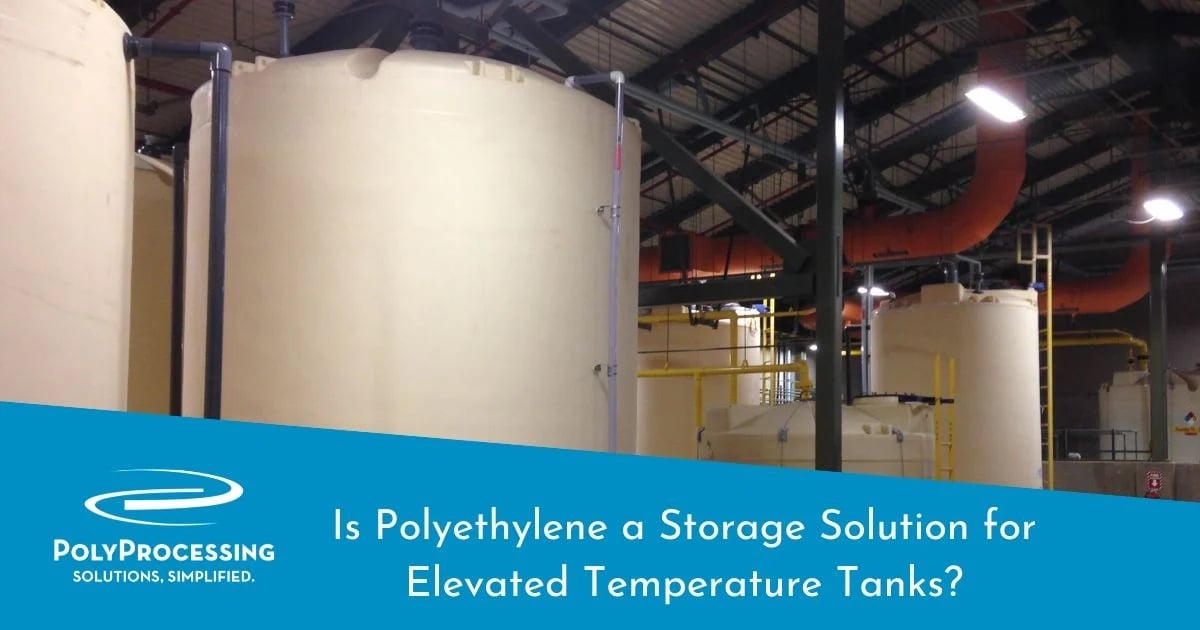

Is Polyethylene a Storage Solution for Elevated Temperature Tanks?

Certain chemicals — such as ferric, alum, and hydrochloric acid — can be inherently higher temperature chemicals. To avert catastrophic failure of your chemical storage tank, a margin of safety is required to manage risk.

Poly Processing manufactures our tanks to meet your specific application requirements — including the type of chemical, the storage conditions, and the temperature of the chemicals you’re storing (among other considerations).

Let’s take a look at the temperature factors you should keep in mind when purchasing a chemical storage tank.

Related: How to Keep Your Chemicals Cool When the Heat Is On

Types of Chemical Temperatures

There are three types of temperatures in chemical storage tanks: process temperature, ambient temperature, and delivery temperature. It’s important to consider each of these temperatures when designing and manufacturing your chemical storage tank.

Process temperature — Temperature of the chemical when it is in use at your facility. Some processes can increase the temperature of certain chemical solutions, especially when you mix them with water or other substances.

Ambient temperature — Temperature of the environment that the chemical is stored in. The ambient temperature of your facility is probably around 70 deg F, but the ambient temperature of an outdoor storage area could fluctuate wildly, depending on the season, the weather, or the time of day. A storage area in direct sunlight can have a noticeably higher ambient temperature than one in the shade.

The ambient temperature can affect chemical temperatures, raising or lowering them according to the surrounding environment.

Delivery temperature — The temperature of the chemical when it’s delivered to your facility. Depending on the distance they travel from the chemical manufacturing facility, some chemicals can have varying temperatures when they are delivered to you. Sodium hypochlorite is one example. If the chemical plant is across town, the delivery temperature can be higher than if it is shipped from farther away.

Even if the process and ambient temperatures will be low, be sure to consider if you’ll need to have a tank that’s designed to receive chemicals at elevated temperatures.

Choosing the Right Storage Tanks for High Temperatures

When storing chemicals at elevated temperatures, it’s critical to choose a chemical storage tank that’s made of the right type of polyethylene. High-density cross-linked polyethylene, or XLPE, is designed to withstand temperatures up to 150 degrees Fahrenheit, depending on the material being stored. This is 10-25 degrees higher than standard linear polyethylene.

XLPE is more rigid than linear polyethylene, and it is able to hold its form and shape at higher temperatures. The likelihood that the poly will flow again is virtually nonexistent.

Some facilities prefer to use stainless steel tanks for storing chemicals at elevated temperatures. Steel tanks handle the task well, but they aren’t a cost effective solution. In most cases, XLPE tanks can perform as well as steel tanks, at one-fourth or one-third of the cost of steel.

Download the Heat System Maintenance Manual

Designing Your Polyethylene Tank for Elevated Temperatures

While XLPE can withstand higher temperatures in most cases (with a margin for safety) without catastrophic failure, we recommend XLPE tanks be designed and manufactured for your specific service application. Your tank should be engineered for proper corrosion resistance, as well.

Higher temperatures create more stress on the chemical storage tank. As polyethylene heats up, it becomes more flexible and the polymer chains begin to elongate under heat and pressure. This is easily addressed by manufacturing tanks that have thicker walls.

Poly Processing’s tank engineers have the expertise to design your tank to safely and reliably store chemicals at high temperatures. Our customers frequently report that their Poly tanks outlast their warranties by many years.

Custom storage solutions and installations in higher temperature environments are possible using XLPE. Please refer to the ASTM D1998, page 6, for specific temperature stress factors using XLPE.

Poly Processing engineers are also available to assist you in the design of developing the correct and safe storage solution for elevated temperature tanks. Talk to a chemical storage tank expert.

Industry News

For over five decades, Poly Processing has been at the forefront of innovation in chemical storage tank design and manufacturing. Reinforcing our commitment to advancing high density crosslinked polyethylene (HDXLPE) tank technology, we are thrilled to unveil our latest update to our vertical storage tank solutions: the 15,500-gallon IMFO tank, the 15,000-gallon Sloped Bottom IMFO tank, and the 15,500-gallon Vertical tank, are all available in specific gravities up to 2.2 design.

These large innovative HDXLPE tanks are designed for exceptional durability, reliable performance, and an extended lifespan across a variety of applications. To enhance protection and prolong service life in oxidative environments, such as those involving sodium hypochlorite, they can be manufactured with our industry-leading OR-1000 engineered resin system, known for its remarkable resistance to oxidative chemicals.

These tanks represent the best engineering and design in the tank manufacturing industry, and they are covered under PPC’s industry-leading warranty.

At Poly Processing, we’re focused on delivering high-quality, forward-thinking solutions to meet the evolving demands of the chemical storage industry.

- July 21, 2025

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

- Why Chemical Storage Tank Wall Thickness Matters and How to Get It Right

- The Best of 2025 - Top 5 Chemical Storage Blogs

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package