Brine Tanks Provide an Alternative for Water Treatment from Fracking Operations

Fracking has changed the dynamic of oil and gas production in the U.S., boosting oil production to its highest levels in more than 14 years. Fracking requires huge amounts of water, adding to already high operating costs for oil and gas companies. Environmental groups have also raised concerns about the waste of precious water supplies at a time when some states are suffering through droughts.

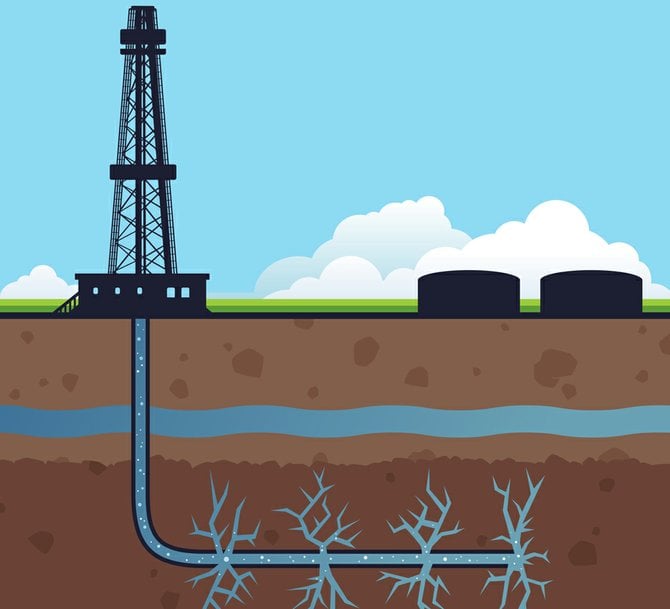

What Is Fracking?

Fracking is a drilling technique that uses hydraulic fracturing and horizontal drilling to discover hidden pockets of oil and gas located in shale rock formations. After a vertical well is fully drilled, it is encased in concrete to prevent tainting of groundwater. Huge amounts of highly pressurized (and sometimes treated) water, up to 9,000 pounds per square inch, are pumped into the well to “fracture” rock formations and release the oil and gas.

Fracking Concerns

While fracking has proven effective in locating and extracting hidden oil and gas reserves, it does have its downfalls. Fracking requires tremendous amounts of water, which means drilling locations need to be serviced frequently by water trucks to fill demand. Along with the added costs, drilling companies are concerned that parades of water tank trucks rolling through once quiet rural towns will create traffic congestion and noise.

What do drilling companies do with the water used during the fracking process? The water used during the fracking process (drilling brine) is often contaminated with concentrations of dissolved solids, such as arsenic, mercury, thallium, chromium, other heavy metals and even NORMs (naturally occurring radioactive materials). The decision of what to do with the millions of gallons of flowback liquid is both a challenge and an environmental concern. Since the drilling brine contains dissolved solids, municipal waste water systems can not treat it. Drillers store the tainted water in pits on site, or haul it away to licensed disposal facilities using water trucks. There is a alternative solution to handling drilling brine.

The Poly Processing Solution: Recycling Drilling Brine

As disposal costs of the tainted waste water increase, and environmental pressures mount, drillers are exploring ways to recycle and reuse the drilling brine on site. Recycling eliminates the cost of disposal and the cost of acquiring fresh water for fracking. It can cut costs by as much as $2.50 per barrel in some areas, meaning as much as a $250,000 - $500,000 savings over the lifetime of a typical well. This also decreases the traffic created from hauling the water in and out of the well site.

Storing the drilling brine on site in polyethylene tanks provides a cost effective solution to an otherwise difficult situation. Poly Processing’s cross linked tanks offer light-weight design and robust durability (meeting the ASTMD 1998 Standards), allowing for a longer service life. Additionally, wind/seismic restraints can be added to safely secure the tanks.

For more information about how we can help make your drilling operation more effective, please contact a storage tank specialist.

- March 25, 2014

- Topics: Applications

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package