Understanding the Impact of UV Exposure on Chemical Storage Tanks

For over five decades, Poly Processing has been at the forefront of innovation in chemical storage tank design and manufacturing. Reinforcing our commitment to advancing crosslinked polyethylene (XLPE) tank technology, we are thrilled to unveil our latest update to our storage tank solutions: the 15,500-gallon IMFO tank, the 15,000-gallon Sloped Bottom IMFO tank, and the 15,500-gallon Vertical tank, are all available in specific gravities up to 2.2 design.

These large innovative XLPE tanks are designed for exceptional durability, reliable performance, and an extended lifespan across a variety of applications. To enhance protection and prolong service life in oxidative environments, such as those involving sodium hypochlorite, they can be manufactured with our industry-leading OR-1000 engineered resin system, known for its remarkable resistance to oxidative chemicals.

These tanks represent the best engineering and design in the tank manufacturing industry, and they are covered under PPC’s industry-leading warranty.

At Poly Processing, we’re focused on delivering high-quality, forward-thinking solutions to meet the evolving demands of the chemical storage industry.

%20Tanks%20UV%20Resistant%20(1).jpg?width=878&height=461&name=Are%20Polyethylene%20(HDPE)%20Tanks%20UV%20Resistant%20(1).jpg)

Anytime a chemical storage tank is located outdoors, it’s exposed to harmful elements, such as sun, wind, and rain. Poly Processing recommends taking special considerations to protect the life of your storage tank, especially from damaging ultraviolet rays.

Let’s explore solutions you can implement to protect polyethylene chemical storage tanks from damage due to UV exposure.

UV Exposure Is Bad for Your Storage Tanks

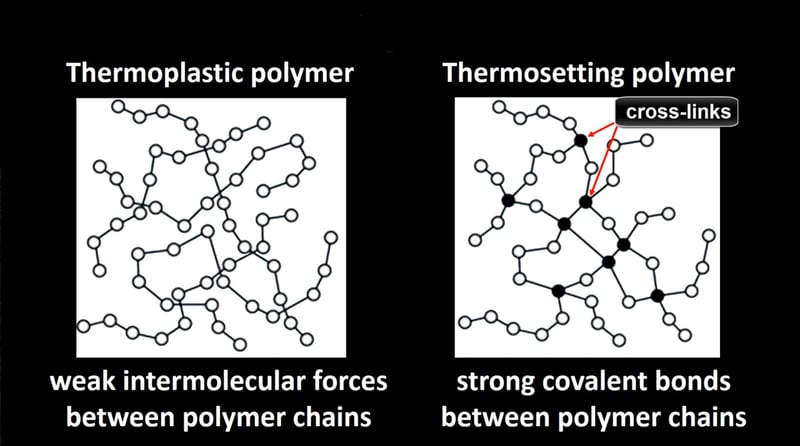

When crosslinked polyethylene (XLPE) tanks are manufactured, bonds form between atoms on polyethylene molecules. The molecular chains become linked together in a vast network, which gives the material its durability and strength. UV light can attack these molecular bonds.

Download Our XLPE Comparative Study

Extended exposure to sunlight radiation and ultraviolet rays results in weathering of all polyethylene storage tanks. Without proper protection, UV light causes a compound breakdown of the polyethylene elements, making the polyethylene tank brittle. This can cause microcracks, leading to leaks and potential failure of the chemical storage tank.

Exposure to UV light is a problem for any plastic product when long term performance is essential. However, some polymers are more resistant to serious degradation than others, such as crosslinked polyethylene. XLPE chains can provide more protection than linear polyethylene. Poly Processing’s XLPE chemical tanks in most cases aren’t susceptible to the serious reactions of linear polyethylene, such as potential catastrophic failure and unzipping.

View the illustration below to see the difference between linear polyethylene, which is a thermoplastic polymer, and crosslinked polyethylene, which is a thermoseting polymer.

Download our Carbon Black & Plastics technical bulletin for more information about the impact of ultraviolet light on various resins.

If you can’t place your chemical storage tank indoors or under a lean-to shelter or covering, manufacturing the tank with carbon black resin is a great option for UV protection.

Carbon Black Is a Great Choice for UV Protection

Carbon Black is a nearly pure, elemental carbon. When used as a resin in the molding of the polyethylene tank, it acts as an absorber of ultraviolet light. UV energy is absorbed, transformed into heat, and dissipated throughout the tank. While Carbon Black polyethylene tanks tend to have slightly higher temperatures than light-colored tanks, the difference is nominal.

The UV index value or rating of carbon black, according to an ExxonMobil study, supports carbon black as a superior UV resistant material.

Adding carbon black is a simple, inexpensive solution. It’s the preferred pigment of many of our customers especially when storing harsh chemicals outdoors.

.jpg?width=567&height=425&name=IMG_0523%20(2).jpg)

What About Temperature Concerns?

While black tanks have a slightly higher overall temperature than natural or white tanks, the UV protection that carbon black provides outweighs the effects of slightly elevated temperature levels. The useful life of the tank is extended and the potential for catastrophic failure is reduced significantly. As a result, carbon black is the preferred compounded pigment for storing harsh chemicals such as sodium hypochlorite and other aggressive materials.

It takes a tremendous amount of energy to heat up all of the chemical in a storage tank, no matter what color the tank is. That’s because by the time the temperature starts to rise, the sun is already setting, and ambient temperatures are cooling down.

Ambient temperature, or external atmospheric temperature, has little effect on the tank or the chemical content in the tank. That’s because ambient temperatures fluctuate too quickly to affect the chemical. First, the heat needs to penetrate the plastic tank, then it needs to heat hundreds or thousands of gallons of chemicals.

Even in the hottest areas of the country, by the time the environmental temperature begins to warm the chemical, the sun is already descending and the ambient temperature is falling.

So black tanks are a great choice for UV protection.

Another way to protect your tank is to paint it or in some cases insulate it and paint it.

Painting Your Own Tank for UV Protection

Painting the tank can reflect the UV rays and help reduce heating. If you paint your polyethylene tank, it's best to do it on-site. This allows the surface to oxidize a bit and also protect it from potential scratches during transportation and installation.

We recommend lightly bead-blasting the tank surface before painting, to ensure the paint adheres. You can also set the tank in the sun for a few months and allow the outer surface to oxidize naturally, then apply the paint.

If you choose to paint your chemical storage tank, be sure to follow proper procedures and to use a paint that won’t crack or flake with tank expansion. An acrylic or elastomeric paint, which expands and contracts with the tank, is best.

Painting a polyethylene tank is similar to painting the outside of a home or business. Paint can be applied in the traditional ways using airless sprayers, power sprayers, rollers, or even brushes but surface preparation is a key.

Insulation and Paint

If you’re located in a hot area like Arizona or Florida, we often have customers who insulate and paint their tank to protect it from ambient heat. Together, insulation and paint do an excellent job of blocking UV rays while maintaining a cooler temperature of the chemical being stored. Upon request, we can apply two inches of insulation and a coating of industrial grade paint at the factory before your tank ships.

This is often an ideal solution for chemicals that degrade under higher temperatures, such as sodium hypochlorite.

For questions regarding outdoor polyethylene storage tanks, or for a custom storage tank system solution, contact a Poly Processing storage tank specialist.

- April 28, 2025

- Topics: Fittings and Accessories, Applications

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package