Key Differences: Molded Full Discharge vs. Post-Production Insert

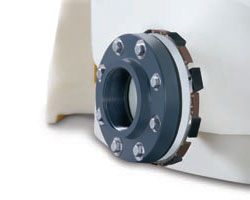

One of the biggest challenges in vertical tank design is maintaining the tank’s integrity while still allowing for the tank to be discharged, cleaned, and properly maintained. Some companies create tanks out of one substance and insert a flange, post-production, for drainage and discharge. This works fine, to a point, but there are other alternatives, like Poly Processing’s IMFO (Integrally Molded Flanged Outlet).

An inserted flange is common in the chemical tank industry, but there are decided benefits to a molded full discharge. The main differences lie in impact on the structure and structural integrity, net positive suction possible, and the discharging capabilities of the tanks.

Let’s take a look at the main differences between a molded full discharge, and a post-production insertion.

Structure and Structural Integrity

One-piece construction enhances long-term integrity, both for the tank as a whole and in the knuckle radius, which is the point where the floor of the tank meets its sidewall. The knuckle radius is the thickest part of the tank; so adding an insert post-production compromises the tank. An insert can impact the tank's hoop integrity as well, which puts the entire tank at risk of structural stress from volatile chemicals. When the insert is made of metal, you can run into a whole new set of problems. Chemical reactions in the place where the tank material meets the metal of an insert can create a stress point for the plastic itself. This can cause leaks or cracks over a small amount of time.

Net Positive Suction

In a tank with an inserted discharge, static head pressure for net positive suction must be managed carefully, since some chemicals have vapor pressure that needs regulation. An unexpected advantage to a discharge that is molded into the tank design itself, like the IMFO® design from Poly, is that it creates the highest amount of static head pressure so you can get the highest net positive suction of any vertical tank that's not a cone tank. That means safer tanks that last longer.

Tank Maintenance and Full Discharge

A molded discharge is also a discharge that can empty completely versus a post-production flange that is inserted one to two inches above the knuckle radius. That one to two inches makes a big difference when the chemical being stored creates sediment – such as sodium hypochlorite does, for example.

A tank that cannot discharge that bottom sediment could require manual cleaning, a dangerous and time-consuming process. The ability to fully discharge the tank is a big advantage to molded full discharge.

A molded full discharge provides a number of benefits to a chemical tank storage system that a post-production insert simply cannot. Poly Processing is constantly researching and creating innovative solutions to make tanks safer and more efficient.

To learn more about the details and advantages of a molded full discharge, download our IMFO Guide today.

- February 12, 2015

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package