Fats, Oils, and Grease Storage. Why Crosslinked Polyethylene?

FOG is an acronym for fats, oils and grease, particularly in the context of wastewater collection systems. FOG comes from meat fats and food scraps, cooking oil, shortening, lard, butter and margarine, gravy, and food products such as mayonnaise, salad dressings, sour cream and other foods high in fat.

Fats, oils, and grease present a major challenge to municipal solid waste and wastewater treatment operations — but it’s becoming a problem for businesses, too. They pose a frequent and costly challenge for sewer systems because they cause blockages and corrode pipes.

Many wastewater blockages can be traced to accumulated FOG that results in sewage spills, manhole overflows, and sewage backups. Many municipalities with tight operating budgets are passing the cost and responsibility of storing and disposing of FOG along to businesses.

For small restaurants with limited hours and dishwashing, a grease trap is usually adequate to handle fats, oil, and grease waste. Large volume restaurants, hotels, casinos, hospitals, school kitchens, and cafeterias require a larger volume grease interceptor.

A grease interceptor is a vault or storage tank, with a minimum capacity of 500-750 gallons, located on the exterior of the building. The grease interceptor operates in the same manner as a grease trap, but it handles a much larger volume of fats, oils, and grease waste. The waste water cools within the tank, permitting the FOG time to congeal and rise to the surface for removal and disposal.

Designing an Interceptor System

For the grease interceptor system to work properly and cost effectively, it’s critical to ensure proper design, installation, and maintenance. One important design consideration is determining the correct size of the tank, based on the volume of wastewater and fats, oils, and grease.

Other design considerations include:

- Secondary containment to prevent a spill or leak of FOG

- Proper flexible piping and connections to accommodate tank expansion and contraction

- Top or sidewall manway covers to easily remove and dispose of the fats, oils, and grease

Polyethylene Interceptor or Storage System

A polyethylene grease interceptor tank offers design flexibility and some cost advantages over steel or fiberglass tank options. Poly Processing tanks are easier and less expensive to maintain, because they are less prone to the pinholes and microcracks that steel and fiberglass tanks can possibly develop. Lightweight polyethylene storage tanks are less expensive and easier to transport and install.

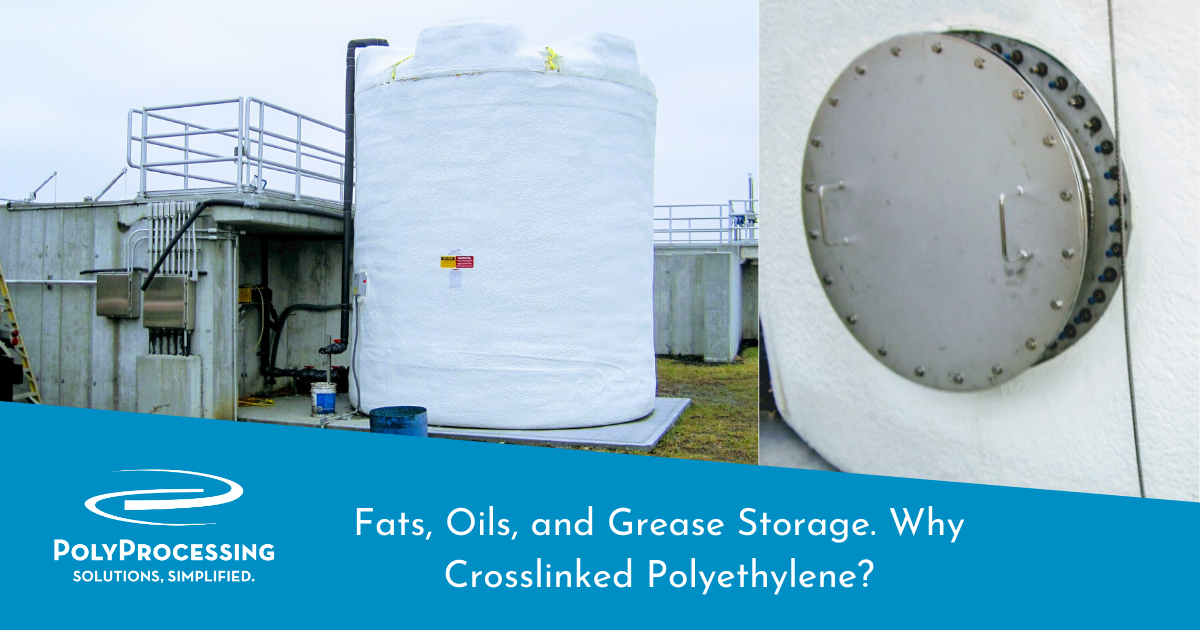

Many wastewater treatment plants use our tanks for fats, oils, and grease storage before they’re processed in their system. We recommend using the IMFO® or Sloped-Bottom IMFO Tanks, with heating pads and insulation to keep the FOG warm enough to flow if necessary. Adding a side manway makes cleanout easier and gives you access to the inside of the tank from ground level.

The Sloped-Bottom IMFO Tank in most cases costs much less than a cone-bottom tank with a stand and basket. It will cut the costs of tank upkeep and fosters improved employee safety over the long-haul.

Poly’s sloped-bottom tank design allows chemicals and heavier substances, such as sludge and FOG (fats, oil, and grease) to discharge easily. And because it incorporates the IMFO (Integrally Molded Flanged Outlet) discharge fitting at the very bottom of the sidewall, you’ll get full discharge capabilities. The flange is at the bottom of the tank and the tank floor is sloped, therefore complete full discharge is achieved below the tank knuckle radius, eliminating the need to enter the tank for cleaning. There are very few to no residual materials to clean out in most cases.

The Sloped-Bottom IMFO is a rotationally molded high-density cross-linked polyethylene tank. It is one single piece with no seams. Because the slope and flange are molded directly into the tank, there are no cut in drain fittings and less chance of leaks or stress cracking.

The one-piece construction also enhances the tank's long-term performance, since it doesn’t compromise the tank hoop’s integrity or structural design.

For more information on storing FOG, download our Fats, Oils, and Grease Guide.

Or, contact a Poly Processing storage system specialist to design a grease interceptor system to handle storing and removal of fats, oils, and grease.

- February 17, 2025

- Topics: Chemicals

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package