Poly Processing Innovation Series: The IMFO® Is a Better Full Discharge System

This is the second article in Poly Processing’s Innovation Series, where you’ll discover the many innovations that we have introduced to the chemical storage industry.

One of the biggest challenges in vertical tank design is maintaining the tank’s integrity while still allowing for the tank to be fully discharged, cleaned, and properly maintained.

Traditional tank maintenance can be a challenge with many chemicals — so Poly Processing Company has developed a unique full discharge system that helps minimize the hazards associated with traditional vertical tank maintenance.

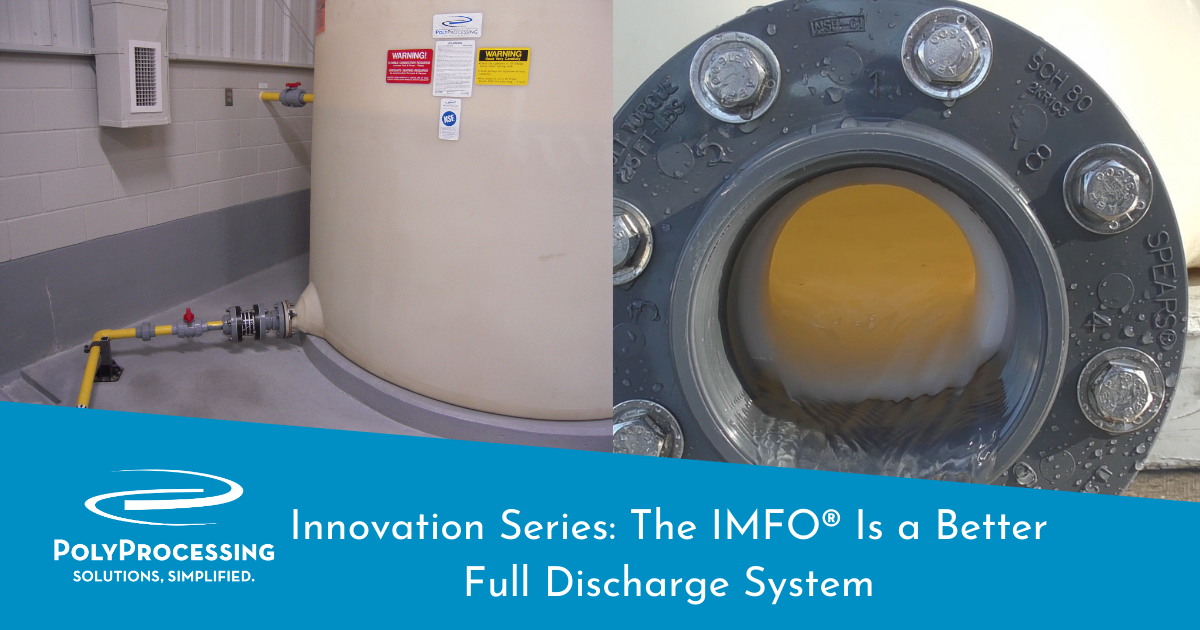

Poly Processing’s Integrally Molded Flanged Outlet (IMFO®) Tank, is a homogenous flange system that is molded as part of the tank while it is being manufactured, making it a stress-free part of the tank. The flange is created from the same material as the tank — it’s not an insert added during or post-production.

Some companies create tanks out of one substance, but they either mold in a threaded metallic flange for drainage and discharge, or they install it post-production. This is simply to save money on investing in proper mold tooling to make the right tank. An inserted metallic flange is common in the tank industry, but there are critical benefits to using a molded full discharge fitting or IMFO.

Let’s take a look at the main differences between a molded full discharge fitting, and a post-production or molded metallic insert.

Structure and Structural Integrity

One-piece construction enhances long-term integrity, both for the tank as a whole and in the knuckle radius — the point where the floor of the tank meets its sidewall. The knuckle radius is the thickest part of the tank, so adding an insert post-production or during production can compromise the tank. An insert can impact the tank’s hoop integrity as well, which puts the entire tank at risk of structural stress from volatile chemicals.

Since the insert is made of metal, you can run into a whole new set of problems. Chemical reactions in the place where the tank material meets the metal of an insert can create a stress point for the plastic itself. This can cause leaks or cracks over a short time. Also, there are different expansion and contraction coefficients between the plastic and metallic materials which can cause leakage.

IMFO: The Superior Full-discharge Solution

An IMFO Tank delivers a number of benefits to a chemical tank storage system that a metallic insert simply can’t offer. These include:

- Full tank discharge, because the flange is at the bottom of the sidewall, below the tank knuckle radius. There’s no need to enter the tank for cleaning.

- Enhanced long-term performance and fuller useful life of the tank since the flange doesn’t compromise the tank’s hoop integrity or structural design.

- Complete flange face protection is available in aggressive oxidation environments. The antioxidant OR-1000™ system can protect the discharge components from deterioration.

- Highest amount of static head pressure. The IMFO’s design brings you the highest net positive suction head (NPSH) of any vertical non-coned tank on the market.

- Any required maintenance is simple and hassle-free. Unlike metallic inserts, the flange extends away from the tank wall and the entire flange system is external with easy hardware access from outside the tank.

- There are no chemical compatibility issues like the ones you may encounter with metallic inserts. If the chemical is safe in a crosslinked polyethylene tank, it’s safe discharging out of the IMFO system.

Tank Maintenance and Full Discharge

A molded full discharge system can empty the tank completely, versus a post-production flange or metallic insert that is installed one or two inches above the knuckle radius. That inch or two makes a big difference when the chemical being stored creates sediment — such as sodium hypochlorite does, for example.

A tank that can’t discharge the bottom sediment will mean manual cleaning, a dangerous confined space situation, and time-consuming processes. The ability to fully discharge the tank is a big advantage to molded full discharge.

The Vertical IMFO Tanks are available up to 15,500 gallons and the Sloped Bottom IMFO Tanks are available up to 15,000 gallons.

Get more details about the IMFO system and discover the advantages over other discharge systems. Download our full discharge eBook.

- August 5, 2024

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

- Why Chemical Storage Tank Wall Thickness Matters and How to Get It Right

- The Best of 2025 - Top 5 Chemical Storage Blogs

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package