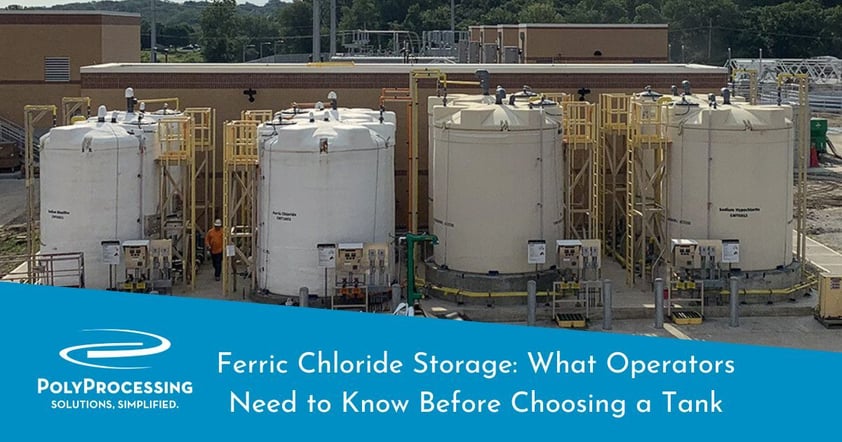

Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

Ferrics, alums, and polymers are commonly used to treat water and wastewater. There are several reasons why these substances require specialized storage:

- Separation, settling, and coagulation are major issues with these chemicals – and those conditions can be compounded by temperature variations.

- Settling and separation issues can make it difficult to pump the chemicals.

- The chemicals are often delivered at elevated temperatures, testing a tank's expansion and contraction capabilities.

- Ferrics create fumes that can defoliate surrounding trees and plants.

- Polymers can act as an environmental stress-cracking agent.

By providing the right kind of storage for these chemicals, safety can be maintained and the integrity of the product can be preserved.

A flocculant is a substance that promotes the clumping of particles so that they may be removed from water. Flocculants are essential in proper water treatment. One particularly popular flocculant is Ferric Chloride.

Ferric Chloride has been commercially available in the United States since the 1930's, but it is only in the last 20 years that we've seen a trend of increased acceptance of Ferric Chloride for drinking water treatment. This trend is likely due to the chemical's improvements in product economics, quality and availability in the United States.

How Is Ferric Chloride Produced?

As one of the purest and most concentrated forms of iron commercially available for water treatment, Ferric Chloride has a unique distinction. In order to produce Ferric Chloride, Ferrous Chloride must be used. Oxidation of Ferrous Chloride with Chlorine creates this new compound.

Using Ferric Chloride in the Water Treatment Industry

Ferric Chloride offers versatility in the water treatment industry, serving as a flocculant and coagulant, as well as a reactant. It promotes faster sedimentation in general and, specifically, better sedimentation in cold water, making it an ideal choice for the industry.

Ferric Chloride has several applications in the potable water industry, including both high and low turbidity removal, enhanced coagulation, NOM (natural organic matter), DBP (disinfection by-products) precursor removal, color removal, arsenic reduction, softening solids sedimentation aid, and as a filtration aid.

Safely Storing Ferric Chloride

It is extremely important that we handle Ferric Chloride and all chemicals with respect and in a safe manner. This holds true to safe chemical storage as well.

Ferric Chloride is also used as an etching medium, meaning it should not be stored in a FRP tank, as the chemical would compromise the tank. For safe storage, we recommend a high-density crosslinked polyethylene tank.

Not all high-density polyethylene tanks are created equal. Although they sound nearly identical, linear polyethylene and crosslinked polyethylene (XLPE) chemical storage tanks have significant differences. Those differences could impact your organization’s bottom line, your people’s safety and the operations of your facility.

Both linear polyethylene and XLPE tanks are made from heated resins to form cured plastic. However, the differences in their production create very different polyethylenes with very different structural strength.

Crosslinking is simply the formation of bonds between the polymer chains. These bonds, equal in strength and stability to the principal bonds along the polymer backbone, tie the polymers together, thus dramatically increasing molecular weight. In fact, the length of the polymer chains and, therefore, the physical properties, are much better than can ever be achieved without crosslinking.

The result is a plastic that possesses impact resistance, tensile strength and resistance to fracture that linear polyethylene just can’t match. These qualities make crosslinked polyethylene an excellent choice when tank integrity is critical. The structural integrity, heat resistance and useful life in most cases are unparalleled.

Poly Processing has NSF-61 certification for 38 chemicals on its crosslinked polyethylene tanks.

Ferric chloride is also a high fuming chemical. These fumes can potentially defoliate surrounding trees and plants.

When storing Ferric Chloride in a chemical storage tank, a fume-tight manway lid cover prevents fumes from escaping the tank. Adding a scrubber provides a cost-effective solution to address any potential fuming into the atmosphere while using ferric chloride.

Our crosslinked polyethylene tanks are able to store up to 96% concentration of Ferric Chloride, with a tank that has a specific gravity rating of 1.65, with PVC fitting materials, EDPM gaskets, and titanium bolts.

Learn more about Ferric Chloride by downloading our complete product catalog today, or contact a chemical storage tank expert to get answers to your questions.

Additional Considerations When Storing Ferric Chloride

Ferric chloride is widely used in water and wastewater treatment because of its effectiveness as a coagulant. While it is a familiar chemical in many plants, its corrosive nature means storage details matter more than many operators expect.

The following considerations build on the existing guidance and address common issues seen in long-term ferric chloride storage applications.

Ferric Chloride Concentration and Tank Design

Ferric chloride is commonly delivered and stored in concentrations between 30 percent and 42 percent by weight. As concentration increases, so does specific gravity.

Tank selection should account for:

- Actual delivered concentration, not nominal values

- Specific gravity of the solution

- Continuous fill level and head pressure

Using an underspecified tank can lead to excessive wall stress and reduced service life, even when the material itself is chemically compatible.

Differences Between Ferric Chloride and Other Coagulants

Ferric chloride behaves differently than alum and many polymer coagulants.

Compared to alum, ferric chloride:

- Has a lower pH

- Is more aggressive toward metals

- Places higher demands on fittings and penetrations

Facilities converting from alum to ferric chloride often overlook these differences, which can lead to premature failures if storage systems are not reevaluated.

Fittings, Gaskets, and Connection Details

In ferric chloride systems, fittings are often the first components to fail.

Best practices include:

- Minimizing exposed metal components

- Using chemically compatible gasket materials

- Allowing flexibility in piping connections to reduce sidewall stress

All connections should be inspected periodically, especially during the first year of operation, when settling and thermal movement are most likely to occur.

Secondary Containment and Regulatory Expectations

Ferric chloride is regulated as a corrosive substance, and many jurisdictions require secondary containment to reduce environmental risk.

Secondary containment may be achieved through:

- Double-wall tank systems

- External containment basins

- Engineered containment structures

Containment requirements vary by location, so facilities should confirm expectations with local environmental authorities before installation.

Temperature and Environmental Exposure

Ferric chloride is typically stored at ambient temperatures, but environmental conditions still influence system performance.

Higher temperatures can:

- Increase chemical aggressiveness

- Accelerate degradation of non-compatible materials

- Shorten the life of fittings and accessories

Tanks should be installed away from direct heat sources and designed to maintain acceptable process temperatures during normal operation.

Inspection and Preventive Maintenance

Routine inspection plays a key role in long-term ferric chloride storage reliability.

Recommended practices include:

- Visual inspection of fittings, vents, and gaskets

- Verifying vent lines remain unobstructed

- Monitoring for surface changes or discoloration

Annual inspections should follow the manufacturer’s installation and operation guidance to ensure continued safe operation.

Planning for Long-Term Ferric Chloride Storage

Ferric chloride is effective, economical, and widely used. It is also unforgiving when storage systems are not properly designed.

Matching tank material, design, fittings, and containment to the specific application helps reduce maintenance costs and unplanned downtime over the life of the system. Working with an experienced manufacturer such as Poly Processing helps ensure ferric chloride storage systems are specified correctly from the start.

- February 16, 2026

- Topics: Chemicals

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package