Better and Safer Alternatives to Downpipes

When customers inquire about installing downpipes in Poly Processing chemical storage tanks, we strongly recommend against it for several important reasons.

.jpg?width=804&height=422&name=Better%20and%20Safer%20Alternatives%20to%20Downpipes%20(1).jpg)

One of the main reasons to avoid downpipes is the difficulty of field installation. Installing or repairing a downpipe encourages or requires someone to enter the tank to set the downpipe floor supports, fix a float, repair a bottom support brace, replace a pipe, etc. which are all hazardous tasks.

Additionally, there are multiple other reasons why we recommend no downpipes in a tank. Here are several reasons why we have developed safer and better alternatives to downpipes:

- Safety in avoiding confined space entry - No one should enter a tank to install or repair an accessory.

- Maintenance and repair benefits – Alternatives allow simpler solutions to issues that can develop over time.

- Ease of field installation - Our application alternatives below can be installed or repaired from the outside of the tank.

- Lowering system cost - Downpipes are expensive to install and maintain.

- Shipping integrity and costs - Less accessories to break or be damaged during transport.

- Extended tank Life from easing tank wall stress - Poly Processing prides itself on the strength and useful life of our crosslinked tanks and discourage downpipes that can shorten the life of a tank.

- Overall ease of business - Using our alternatives to downpipes gives you a peace of mind knowing that no one will have to enter a tank to install or repair a PPC product.

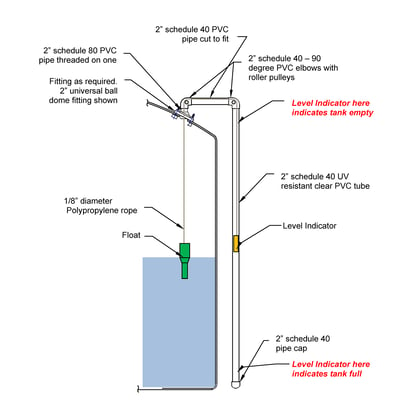

Reverse Float Level Gauge

In the past, Poly Processing’s reverse float level gauge came with a perforated downpipe. This was used to prevent the float from drifting sideways and to keep it in a vertical plane. The downpipe was unnecessary, however, because the float would only tend to drift during fill cycles, not while the fluid was at rest.

In the past, Poly Processing’s reverse float level gauge came with a perforated downpipe. This was used to prevent the float from drifting sideways and to keep it in a vertical plane. The downpipe was unnecessary, however, because the float would only tend to drift during fill cycles, not while the fluid was at rest.

Without the perforated downpipe accuracy will be slightly diminished but the safety in the field for personnel will be much greater due to no tank entry issues. This product was never intended to be an exact measurement tool in the first place. By removing the downpipe, benefits listed earlier are realized, while the slight decrease in accuracy is only relevant during the filling of the tank, which the operator and truck delivery personnel should not be relying on anyhow. More precise methods of chemical fill should be relied on between the operator and delivery service to not overfill the tank. Poly Processing can provide several digital level instrumentation options to give more accuracy to exact fluid level.

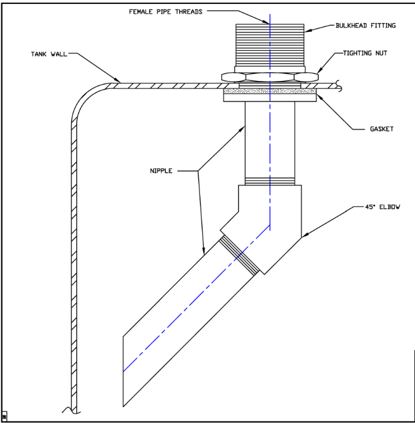

Fill Line

Downpipes on fill lines often cause a jack hammering effect to the bottom of the tank. This jack hammering vibration or shockwave is caused by pump or air pressure fighting against the fluid dynamic head pressure and can cause damage to the floor of the tank from movement. This practice would void tank warranty as we recommend against it in our Installation, Operation, and Maintenance Manual.

A better and much safer alternative to a downpipe is our anti-foam fill assembly. This assembly achieves the same goal of not splashing or foaming chemicals during fill. It directs the liquid, using a 45-degree elbow and pipe nipples, to the sidewall of the tank instead of the liquid free falling directly into the tank. See the drawing here.

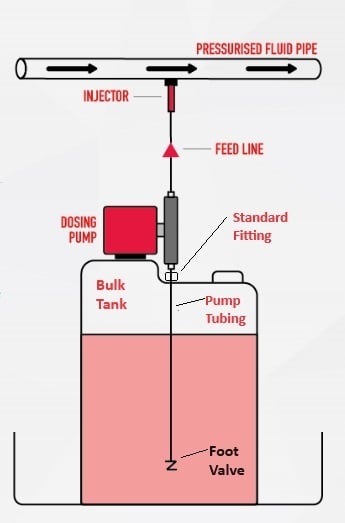

Suction Lift

Downpipes are occasionally requested as a feed pipe for pumping chemical towards the tank dome for pump suction lift. Again, to achieve benefits of safety and others listed above, a very good alternative is available. In fact, in this scenario, additional benefits apply to assisting suction lift. Most chemical metering pump companies offer weighted foot valves and drop-in tubing it connects to, providing the needed suction lift out of a tank. These items are also available from standard plumbing supply stores. The tubing and valve unlike a drop pipe can be primed during installation from the manway and maintain prime, dramatically assisting a pump suction lift application. These foot valves can include a filter which helps protect the metering pump from coarse solid particles. Foot valves come in various materials including polypropylene, PVC, PVDF, and PTFE.

Downpipes are occasionally requested as a feed pipe for pumping chemical towards the tank dome for pump suction lift. Again, to achieve benefits of safety and others listed above, a very good alternative is available. In fact, in this scenario, additional benefits apply to assisting suction lift. Most chemical metering pump companies offer weighted foot valves and drop-in tubing it connects to, providing the needed suction lift out of a tank. These items are also available from standard plumbing supply stores. The tubing and valve unlike a drop pipe can be primed during installation from the manway and maintain prime, dramatically assisting a pump suction lift application. These foot valves can include a filter which helps protect the metering pump from coarse solid particles. Foot valves come in various materials including polypropylene, PVC, PVDF, and PTFE.

While Poly Processing Company advises against using downpipes, we may accommodate the insistence of a designer, as an exception with a nonstandard drop pipe accessory. This exception could likely result in additional labor and material costs, additional quote return time, and product delivery time.

Poly Processing strongly recommends NOT getting inside a tank. Do not let a downpipe be a reason to do so when better alternatives exist. Our own Field Service team does not enter a tank, but instead has a myriad of techniques and methods (using ropes, cables, & special tools) for performing inspections and repairs all from outside the tank.

Poly Processing strongly recommends NOT getting inside a tank. Do not let a downpipe be a reason to do so when better alternatives exist. Our own Field Service team does not enter a tank, but instead has a myriad of techniques and methods (using ropes, cables, & special tools) for performing inspections and repairs all from outside the tank.

Furthermore- Entering a tank falls under "confined space" work as defined and regulated by OSHA. If the tank has had chemical in it, OSHA uses the term "permit-required confined space" (permit space) to define and regulate many requirements and often permitting before entering a tank. Poly Processing has experienced product specialists to discuss any application. If a downpipe is still desired, let us review the application with you and see if a safer and more effective solution might be available.

- March 25, 2024

- Topics: Fittings and Accessories, FAQs

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package