How to Safely Store Sulfuric Acid to Overcome its Corrosive Nature

Sulfuric acid (H2SO4) is an NSF/ANSI 60 approved chemical at a 98% concentration or less. Poly Processing’s tank systems are NSF/ANSI/CAN 61 approved to store Sulfuric acid at 98% concentration or less.

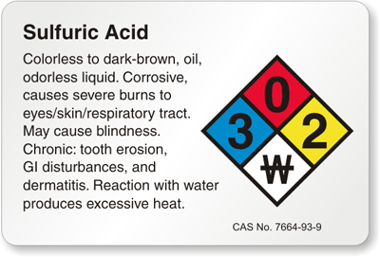

Sulfuric acid is a highly corrosive mineral acid that challenges traditional storage options. This pungent, colorless to slightly yellow viscous liquid is occasionally dyed dark brown during production to alert people to its hazards. The biggest challenges in working with sulfuric acid are that it is an aggressive oxidizer and it is very heavy. These challenges threaten the strength and design of many storage tanks. Poly Processing’s tanks and fittings can be combined specifically to store sulfuric acid and reduce the risks.

Let’s take a closer look at what sulfuric acid is, how it’s used, and how you can overcome its corrosive challenge with the right storage tanks.

What is Sulfuric Acid?

Sulfuric acid is one of the most widely used chemicals in the U.S., with millions of tons produced each year. It’s used in a wide range of applications, including water and wastewater treatment, car batteries, dyes and pigments, mineral processing, fertilizer manufacturing, oil refining, and the manufacture of chemicals.

At high concentrations, sulfuric acid can cause serious damage upon contact. It not only causes chemical burns by way of hydrolysis, but also secondary thermal burns through dehydration. It can cause permanent blindness if it makes contact with the eyes and irreversible damage if swallowed. If sulfuric acid is spilled on metals, it can create highly flammable hydrogen gas.

The leading storage challenges of sulfuric acid are its corrosive nature and its weight. Its corrosiveness impacts a wide range of materials, like metals, living material, stone, and plastic. This is primarily the result of its strong acidic nature. Furthermore, when concentrated it exhibits strong dehydrating and oxidizing properties.

How to Choose the Best Storage Tank for Sulfuric Acid

The highly corrosive nature of sulfuric acid tests the limits of today’s storage systems. There are three considerations when choosing an ideal storage tank—the acid’s corrosiveness, molecular weight, and the concentration being used.

- Corrosiveness. Because it is an aggressive oxidizer, safeguards are required to prevent polyethylene tanks from becoming brittle and cracking, which could result in leaks or failure of the storage tank.

- Molecular Weight. With a molecular weight of 98.079 g/mol, sulfuric acid is an extremely heavy chemical that will test the mechanical integrity of any material.

- Concentration. This acid displays different properties depending upon the concentration being used. It’s used in three main concentrations, based on the end-use application, those are 93-98%, 80 to 92%, and 80%.

Storage Tank Recommendations for Sulfuric Acid

Through a combination of innovative features, Poly Processing overcomes the storage challenges of sulfuric acid with an ideal storage system that contains these features:

- Antioxidant System. When storing sulfuric acid, it’s important to verify the hoop stress rating and understand the specific gravity ratings to make sure the resins used in the storage tank provide a margin of safety. Poly Processing’s next generation OR-1000™ system bonds the HDXLPE with an engineered system — an antioxidant layer that’s an integrated component of the tank. This component drastically minimizes oxidation, reducing the potential for fault and maximizing the useful life of the tank.

- Cross-linked polyethylene tanks. With their robust load tolerance, cross-linked polyethylene tanks can handle the chemical’s heavy weight. Also, the Specific Gravity Rating of 2.2 spg. keeps the tank rigid and gives the end user a built in safety factor and greater useful life.

- High-density cross-linked polyethylene (HDXLPE). The HDXLPE molecular bonding and thick tank wall are particularly important in the bottom third of the tank, where high levels of load are concentrated.

If secondary containment is needed, the Poly Processing SAFE-Tank® is a smart choice. Along with containing the chemical from its surrounding environment, this double-walled tank greatly lowers the risk for hazardous contact of sulfuric acid with water and other materials. SAFE-Tank® systems for sulfuric acid are designed with the OR-1000™ system.

If secondary containment is present, the IMFO® tank is recommended because the tank’s structural integrity is maximized while providing a molded in full drain fitting at the lowest point of the tank sidewall. When combining this tank design with the OR-1000™ system, oxidation is reduced dramatically.

These tank systems are built based on the concentration of the acid. For 93-98% concentration, 2.2 SPG HDXLPE with OR-1000, PVC fittings, Viton gaskets, and 316 SS bolts are used. For 81-92% concentration, 2.2 SPG HDXLPE with OR-1000, PVC fittings, Viton gaskets, and C-276 bolts are used. For 80% or less concentration, 2.2 SPG HDXLPE, PVC fittings, Viton gaskets, and C-276 bolts are used.

Poly Processing chemical tanks are certified to NSF/ANSI/CAN-61 Standards, up to a 98% concentration of sulfuric acid. Poly Processing is the only company with a complete chemical storage tank system certified to NSF/ANSI/CAN-61 Standard. All Poly Processing, OR-1000 chemical storage tank systems and associated fittings adhere to these stringent specifications.

To learn more about properly storing sulfuric acid, check out our complete sulfuric acid storage guide.

- August 4, 2025

- Topics: Chemicals

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package