What to Do If You Spot Chemical Tank Crazing

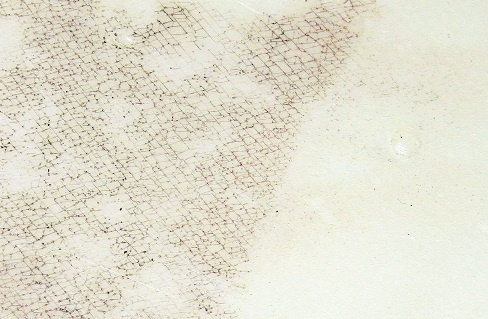

If you’ve seen hairline cracks like spiderwebs on your chemical storage tank, you might wonder if you’re looking at a future problem. That’s a good question.

The short answer is, maybe. The long answer is a little more helpful, and this article will outline next steps for dealing with hairline crackling, called crazing.

What Is Tank Crazing?

Crazing is also called a hairline craze, and it may extend in an unreinforced or reinforced plastic network. A craze is a tiny hairline crack just under the surface of the plastic material. It’s different from a crack because it can’t be felt on the surface—and unlike a crack, it can continue to support a load.

What Causes Crazing?

Crazing can occur because of a myriad of reasons, but for our purposes, it tends to happen under one of these three conditions:

-

Weather: UV attack, rain or other weathering can cause crazing on the outside surface of the tank. This is often the reason for crazing on tank domes.

-

Load conditions due to stress: As the chemical puts physical stress on the walls of the tank, the plastic may develop fine, hairline cracks.

-

Chemical attack: Harsh chemicals, such as hydrochloric acid, can attack the tank wall. Over time, crazing can develop.

Should You Be Worried About Crazing on Your Tanks?

Crazing can be problematic because it can lead to cracking. However, often it never progresses and never becomes an issue for the structural integrity of your tank. If the micro-voids coalesce or start joining each other, then cracks begin to form. That’s when you need to be concerned.

It’s difficult to tell whether the crazing in your tank is harmless or not, simply by looking at it. It takes a trained eye to determine if those micro-voids will continue to grow. If you spot crazing in your Poly Processing tank, the best thing to do is contact Poly Processing and arrange for an onsite inspection or additional help. We’ll send our field service expert to determine if the tank is losing its tensile-load strength or failing, or if it’s simply a matter of UV attack.

Even if the crazing isn’t developing into a crack yet, you’ll need to continue to watch it carefully, because a stress crack could eventually develop in the tank. We recommend conducting a yearly inspection to monitor the development closely.

Related content: Tank Installation Guide

Can you fix it?

The best crazing remedy is prevention. Make sure all your chemical storage tanks have adequate UV protection. Also be sure that you’re using the right type of tank for the chemical you’re storing. Designing your storage system around the chemical is the best way to ensure you don’t have unexpected tank failures.

Once crazing has begun, the best thing you can do is to keep an eye on it and watch for cracking. If a crack begins to form, we can sometimes do some patching to extend the life of the tank a bit, but for the most part, you’re coming toward the end of the useful life of the product.

Need to schedule an onsite tank inspection for crazing? Don’t wait on it. Contact our chemical tank experts today.

- October 19, 2018

- Topics: Chemical Storage

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package