Poly Processing Innovation Series: Enhanced Bellows Transition Fitting for Double Wall Tanks

You’ve heard the adage, “if a job is worth doing, it’s worth doing right.” Poly Processing believes this to be true 110% of the time when it comes to containment. Every single piece of a tank system needs to be completely secure to protect your workspace, your employees, the environment, and the chemical being stored.

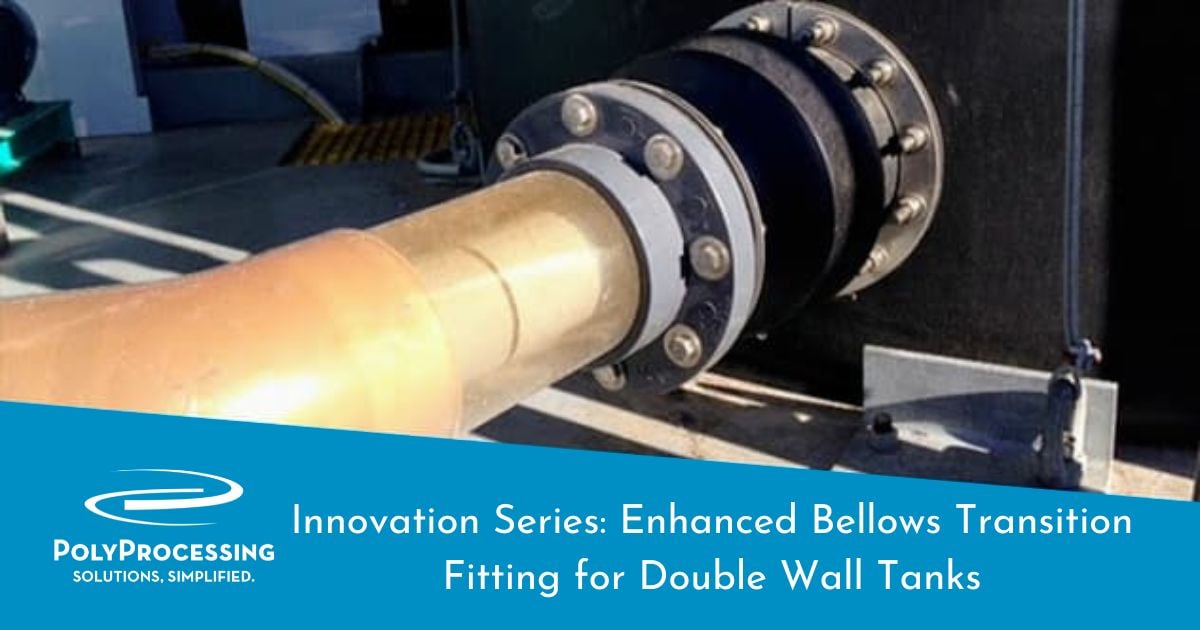

When you install a tank-within-tank or double wall storage tank system like the SAFE-Tank with a sidewall fitting, it may be important to also install a bellows transition fitting. The bellows fitting lets you safely connect the primary tank with the secondary containment tank.

The “Why” Behind the Fully Contained Bellows Transition Fitting

If it’s worth doing, do it right — otherwise, why bother with a containment wall at all? Containment is only as secure as its weakest link. If you’re using a double wall tank system with a sidewall fitting for chemical storage or chemical processing, and you don’t have a bellows transition fitting installed, you may be creating a weak link that could cause trouble.

Many tank owners may not understand the requirements of 40 CFR 264, and they specify transition fittings that aren’t able to contain leaks at the weakest point. Therefore, they act like a single-wall tank. Release from the inner tank may not be contained by the outer tank and could violate the regulations.

In a chemical storage tank situation that calls for emergency containment, a SAFE-Tank, or “tank-within-a-tank” is a great solution that offers 110% containment (or more depending on size) and meets most Federal, state, and local standards for containment.

The most likely potential for a problem, however, is not the tank wall itself, but the drain or pump outlet (i.e., the fitting) on the lower section of the tank wall. Since the tank wall must be cut in order to install a fitting, that connection is more susceptible to pressure, vibration, operating or maintenance errors, and becomes a more vulnerable potential issue than the rotomolded tank wall itself.

A Stronger Link for Your System: The Transition Fitting

The transition fitting fully contains both the fitting and piping from the inner tank, through the outer tank, to the outlet. If the fitting or any of the seals were to be overstressed and fail, the leak would be contained inside the bellows and flow back to the containment space between the inner and outer tank. Such a breach could also trigger a leak detection sensor if one is installed.

This successfully contains potential leaks where the chemical might accumulate between the tank walls. However, many nested tank systems lack this important safety component, and a fitting failure here could most likely siphon the tank contents onto the ground.

Some Solutions Cause More Problems

Some nested tank containment systems place a rubber doughnut fitting between the inner and outer tank at the outlet and then bolt the walls to each other in order to secure this sealing donut. However, this creates a lock or hinge between the two walls, which can negate the installation instruction of allowing the inner tank to move freely. It not only fails to contain; it can create a dangerous hinge point on a system that needs to flex as it fills and empties.

How the Transition Fitting Avoids a Hinge Point

The bellows transition fitting has a flexible expansion joint that is in line with the outlet pipe that runs through both tanks. The inner tank is connected to this transition pipe with a Bolted One-Piece Sure Seal (B.O.S.S.) fitting or PVC Flange fitting.

The containment bellows is a small containment wall or shell around the outlet pipe, which attaches to the outer tank. The inner tank can flex as required, and the fitting is contained with the bellows as explained above.

Installing the bellows transition fitting is important, and it’s worth some additional upfront cost for true containment.

Extra Protection for Your Pipes

If you want even greater protection, tank pipes can be contained with a custom transition fitting and containment piping to contain leaks. This containment option can be clear, so that you can see the condition of the pipe or spot chemical leaks.

You can take things a step further by installing a leak detector in the containment pipe or pump box in case a chemical leak comes out of the pipe. These additional protections to your pipes could potentially save you thousands of dollars over time.

Talk to a chemical storage expert today to learn how to best design your double wall tank system.

- January 9, 2023

- Topics: Fittings and Accessories, FAQs

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Installation Tips for Chemical Storage Tanks: Site Preparation and Offloading

- Understanding pH and Chemical Concentration When Choosing a Chemical Tank

- Maximizing Fill Efficiency: Selecting the Optimal Fill Line System

- Chemical Storage Tanks: A Quick Guide for End Users

- Popular Customization Options for Chemical Storage Tanks

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package