Video: Punishing Drop Tests Prove Our Chemical Storage Tanks Can Take the Impact

Whether you're storing dangerous chemicals or common food-grade materials, reliability of structural integrity is one of the most important factors to consider when purchasing a tank.

Unlike cross-linked polyethylene (XLPE) tanks, linear polyethylene chemical storage tanks can’t stop cracking once it begins. Eventually, the tank experiences catastrophic failure, “unzipping” itself. This is called notch sensitivity. Unfortunately, notches are unavoidable in polyethylene rotomolded storage tanks.

However, you can eliminate a great deal of notch sensitivity by using cross-linked polyethylene (XLPE) tanks, because molecular “bridges” or crosslinks prevent the material from unzipping. Picture a chain-link fence where the metal links are actually bonded or welded together. This is how we are able to design and build cross-linked polyethylene storage tanks to handle the toughest applications.

But it’s one thing to say XLPE tanks perform better—it’s another thing to really put them to the test. To find out if our crosslinked polyethylene tanks would hold up under real-world stress, we subjected cross-linked and linear high-density polyethylene tanks to strenuous conditions. The results were impressive.

The Poly Processing Tank Drop Test Method

Three drop tests were performed, using 3,000-gallon tanks. The first test consisted of two tanks, one made from crosslinked polyethylene and the other from linear polyethylene. The rotomolded tanks were fabricated in accordance with the instructions and guidelines highlighted in ASTM D1998-15. This ensured that these tanks met the quality requirements of optimum cure and proper fabrication.

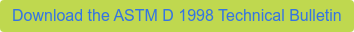

In each test, the tanks were filled with water and dropped onto a concrete surface from a crane.

Drop Test 1

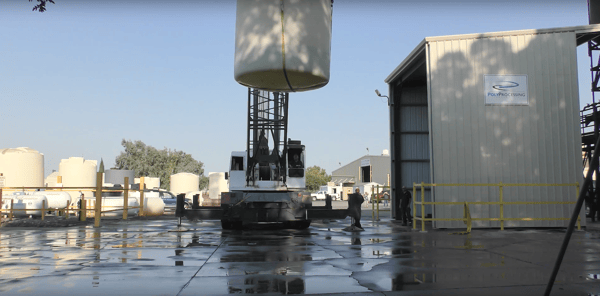

Each tank in the first set was filled with 7,000 pounds of water and lifted by crane 15 feet in the air. The tank was released to free-fall onto a concrete surface below. While the linear tank catastrophically failed, the crosslinked polyethylene tank didn’t fail or develop any cracks.

If you look closely at the linear polyethylene tank, you can see that the impact created a crack that quickly unzipped as the tank finished impacting the ground. This unzipping is a characteristic found in linear polyethylene resin grades.

Drop Test 2

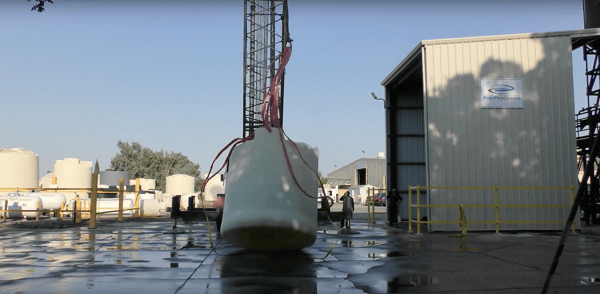

After the first drop, we filled the exact same Poly Processing crosslinked tank with 11,000 pounds of water (more than 15 times the weight of an empty tank). The tank was dropped from the same height, to the same surface with no damage to the tank.

Drop Test 3

Finally, the same tank was dropped from the full height of the crane — 45 feet in the air — onto the concrete surface. Even after the third drop, containing 11,000 pounds of water, the tank remained 100 percent intact with no leaks or cracks.

The Toughest Tanks in the Industry

These tests are an impressive demonstration of our XLPE tanks’ durability and strength, but they’re more than just for show. The strength and longevity of our chemical storage tanks are our top priorities. We’re committed to manufacturing the most robust tanks in the industry — so we’re always working to improve the durability and life expectancy of our polyethylene tank solutions.

Dramatic testing like the drop test allows us to put our liquid storage tanks through the most extreme conditions so that we can guarantee their quality to our customers. Your employees’ safety and your company’s operations depend upon it.

Want to see more tank tests? You can view other Poly Processing quality tests on our YouTube channel.

For more information on the testing we do, contact a chemical storage tank expert at Poly Processing today.

- June 19, 2023

- Topics: Value Added

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package