The Inner Workings of Chemical Storage Tank Venting Systems

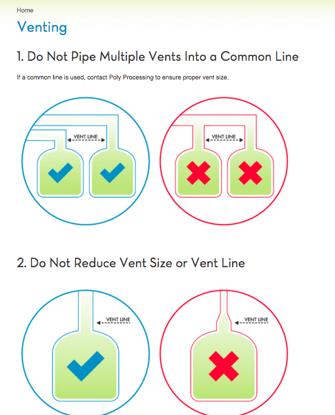

Proper venting of a chemical storage tank system helps ensure safe operation and can also extend the useful life of the cross-linked polyethylene (XLPE) tank. Poly Processing Company sees venting as one of the most critical parts of a safe chemical storage system. We also attach venting labels to tanks manufactured at our facilities to emphasize the critical importance of proper venting.

Our goal is to give users a peace of mind and walk you through the dos and don’ts of proper venting in order to keep it simple, safe, and effective for the end users and operators.

Let's examine how we developed our engineered venting program and help you determine the proper venting for your polyethylene chemical storage tanks.

Tank Pressurization Study

Over-pressurization can cause major problems including tank failure. Because of the risk over-pressurization presents, we commissioned a third-party engineering firm to study the impact of pressure on pneumatically-filled chemical storage tanks with different applications or settings.

The findings from the study include:

- The prevailing industry standard regarding venting was to use a vent one inch larger than the fill line. For example, a two-inch fill line requires a three-inch vent. The study determined this industry standard to be adequate if pumped mechanically but not pneumatically.

- Bulk storage tanks are often pumped off a tanker truck using air. As the rate of pumping increases, so too does the chance for a surge of pressurized air entering the tank. That could result in over-pressurization with standard venting.

- Therefore, the thinking in the market shifted. The standard for proper vent size in pneumatically-loaded polyethylene tanks is now at least double the size of the fill line. For example, a two-inch fill line means using at least a four-inch vent. Doing this allows the air to evacuate at a faster rate and reduces the risk for over-pressurization.

- In addition, the study determined that adding length to a vent over three feet with a 90-degree bend will restrict air flow. This affects recommendations on vent size as well as the number and degree of bends in the venting system.

Choosing the Right Venting System

With those findings in mind, here are some guidelines for picking the right venting system.

While vents add to the initial cost of a chemical tank system, correctly designed and installed venting will help prevent far more expensive occurrences like premature tank failure or even catastrophic failure.

In addition to standard venting, PPC’s SAFE-Surge manway cover ensures that your tank maintains the proper ACFM at all times, even if the primary venting fails.

Customers often ask these questions: Do you have any capacity data for the safe surge manway vent? Is there an SCFM capacity curve or something else that shows how much flow it can pass to keep the tanks below their design pressure? SAFE-Surge is exactly that safety vent.

This SAFE-Surge manway cover is not a standalone vent and should not be coupled with other vent styles to increase venting capacity. It is an emergency vent which provides an added level of safety to your primary venting system.

Because the SAFE-Surge manway cover should never be used as a primary vent, Poly Processing does not keep the flow rate on this emergency vent. SAFE-Surge operates in a manner that will “burp” the tank instead of being a “free flow” style vent. There are calculations that show the flow capacity while fully open, but it will never be fully open when used in the appropriate manner.

For plastic chemical storage tanks where fumes are not a concern, the F.S. 2650® Manway Cover is a less expensive option for safely handling any air pressure surges.

The F.S. 2650 Manway Cover combines a vent and manway cover into one engineered lid system that can evacuate air volumes up to 2650 ACFM, which is well within the calculated maximum potential pressure surges resulting using both two- and three-inch fill lines (maximum ACFM from a two-inch standard line is 910; 1150 from a three-inch line).

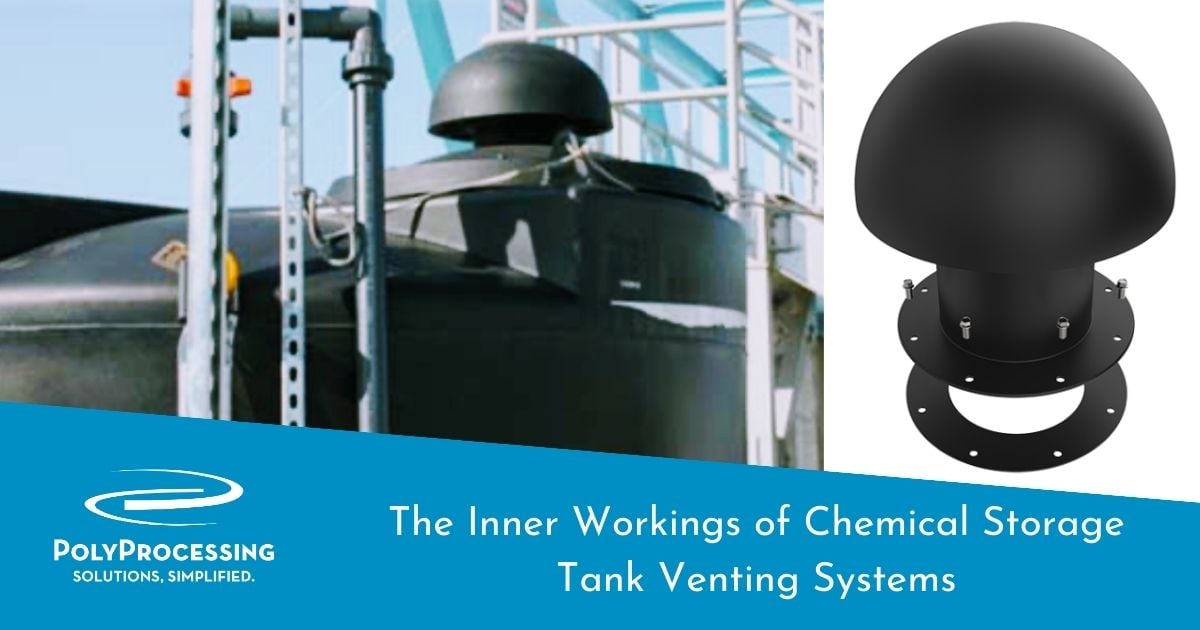

Poly Processing’s Featured Vent Offering

Until now, space-consuming (and expensive) large vents or multiple vents were necessary to meet venting requirements in order to maintain the warranty. Our solution is an 8” mushroom vent, which is available as a complete assembly or as a standalone version.

This mushroom vent has been used by Poly Processing Company for several years as part of the F.S. 2650 manway cover. The vent now comes with a flange molded into it so that it can be installed on the dome of the tank to give you greater venting capacity. This is a more cost-effective alternative to many other venting systems.

Like the F.S. 2650, the mushroom vent comes with an HDPE screen to prevent birds from nesting and debris from plugging the vent.

Performance You Can Depend On

All of our tank venting configurations meet or exceed ASTM D-1998 guidelines for tank pressurization. For your specific polyethylene chemical storage system’s proper venting requirements, it’s best to consult with a Poly Processing chemical storage tank expert. For instance, scrubber applications like hydrochloric acid or acetic acid demand an engineered solution to prevent over-pressurization.

Check out additional venting information, including the Poly Processing venting chart.

How to Size a Tank Overflow

Poly Processing recommends that the overflow fitting/pipe size be larger than the total area or cross section of all inlets that can be pumped simultaneously.

Due to the possible complexities of the specific tank system and tank fill procedures of the tank you are designing, we recommend each tank system be carefully designed / reviewed by a professional engineer who is experienced in tank systems and safe overflow plumbing.

Our venting chart is based on recommendations and criteria from Venting Design for ACFM Technical Paper. More technical information including the third party study is also available on our site.

Contact a chemical storage tank expert for more information on proper tank venting.

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package