The Largest Crosslinked True Full Discharge Tanks Available: 15,500 IMFO and 15,000 Sloped Bottom IMFO

For over five decades, Poly Processing has been at the forefront of innovation in chemical storage tank design and manufacturing. Reinforcing our commitment to advancing crosslinked polyethylene (XLPE) tank technology, we are proud to offer our largest storage tank solutions: the 15,500-gallon IMFO® Tank, the 15,000-gallon Sloped Bottom IMFO® Tank, and the 15,500-gallon Vertical Tank. All are available in specific gravities up to 2.2 design.

These large innovative XLPE tanks are designed for exceptional durability, reliable performance, and an extended lifespan across a variety of applications. To enhance protection and prolong service life in oxidative environments, such as those involving sodium hypochlorite, they can be manufactured with our industry-leading OR-1000™ engineered resin system, known for its remarkable resistance to oxidative chemicals.

These tanks represent the best engineering and design in the tank manufacturing industry, and they are covered under PPC’s industry-leading warranty.

At Poly Processing, we’re focused on delivering high-quality, forward-thinking solutions to meet the evolving demands of the chemical storage industry.

When you combine the best cross-linked resin available with state-of-the-art molds and manufacturing machinery, nothing beats it.

15,500 Gallon IMFO (Integrally Molded Flanged Outlet) Tank

The 15,500 gallon IMFO Tank is good news for the chemical storage industry for four reasons:

- Greater chemical compatibility – Our customers prefer cross-linked polyethylene (XLPE) over fiberglass chemical storage tanks, because of the wide range of chemical compatibility that XLPE offers.

- Tank longevity – The 15,500 crosslinked polyethylene IMFO Tank is built for a long lifetime of reliability and usefulness. The diameter-to-height ratio is excellent for rotationally molded tanks. You can store large amounts of fluid without too much head pressure or hoop stress on the tank wall. As with all of our products, our tanks are designed and built to handle most chemical storage needs.

- It’s cost-effective – Upgrading to the 15,500 IMFO Tank allows you to get more product delivered. In some cases, the new tank can hold 3-4 tanker trucks full of chemicals, depending on what material is being delivered and stored. That means fewer deliveries, and it saves you money.

- It’s robust – To test the strength of our tanks, we performed a series of drop tests on 2,800 gallon tanks. The test tanks were filled with water and raised to a height of 18 feet. We then dropped each tank. A linear polyethylene tank was subjected to the same test. While the linear polyethylene tanks catastrophically failed, the XLPE tanks survived the impact due to the superior strength of material and construction.

In addition, the larger tank diameter allowed us to design the dome so that you can have multiple off-the-shelf fittings installed, if necessary. This introduces a tremendous advantage to your chemical storage options.

In addition, the larger tank diameter allowed us to design the dome so that you can have multiple off-the-shelf fittings installed, if necessary. This introduces a tremendous advantage to your chemical storage options.

Full-Discharge Options

In addition to being easier and safer to clean, the 15,500 gallon IMFO tanks are more reliable over time. IMFO tanks offer a low risk of compromise to the structural integrity of the sidewall. The flange is molded as part of the tank and not added on later like some bulkhead fittings or metallic inserts.

We recommend the 15,000 gallon Sloped-Bottom IMFO Tank for heavier materials such as FOG (fat, oils, and grease) and sludge, and for other full-discharge / drain options. The additional gravity feed allows substances to discharge more easily, making cleaning even simpler because there’s no need for a confined-space entry.

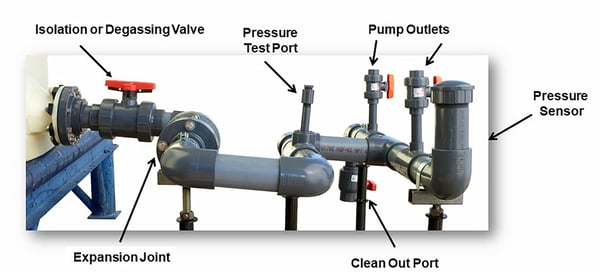

Manifold capabilities are available for the IMFO fitting to give you several useful options off of one fitting, including:

- Isolation Valve or Degassing Valve

- Pressure Test Port

- Pump Outlets

- Pressure Sensor or Transducer connections

- Clean Out Port

Installing a manifold system on the IMFO fitting greatly reduces the number of tank penetrations needed for other fittings. That reduces the potential for leaking fittings.

The 15,500 gallon IMFO Tank and 15,000 Sloped Bottom IMFO tank are available nationally. Check out the drawings and contact a chemical tank specialist to get started on your chemical storage solution.

- September 1, 2025

- Topics: News and Customer Stories, Tank Design and Materials

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package