Properly Storing Hydrofluoric Acid in Chemical Storage Tanks

One of the most popular chemicals in the market that Poly Processing crosslinked polyethylene tanks store is Hydrofluoric Acid. Not only is hydrofluoric acid a commonly used chemical, it's also one of the more dangerous chemicals in use. Safe and proper storage of this chemical is crucial.

Here’s a look at what you should consider when planning for hydrofluoric acid storage.

What is Hydrofluoric Acid?

What is Hydrofluoric Acid?

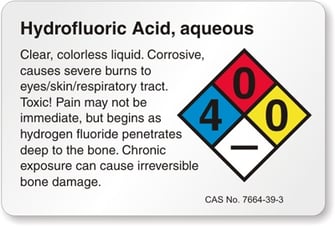

Hydrogen fluoride mixes readily with water to form Hydrofluoric Acid. For all practical purposes, they are considered the same chemical. Hydrofluoric Acid is used extensively in the extraction, processing, and refining of metals, rock, brick, and oil.

The compound is an intermediate for many chemical reactions and syntheses. Hydrofluoric Acid is used to remove rust and to etch, polish, and frost glass. It’s also used to manufacture silicon semiconductor chips. Lastly, Hydrofluoric Acid is used in commercial automotive cleaners, rust removers, and inhibitors for ceramics and fabrics as well as water spot removers.

In wastewater treatment, Hydrofluoric Acid is used to reduce pH and as an emulsion breaker. The chemical is strong enough to be used on treatment pipes to clean up scaling or rusting.

Reducing Risks When Storing Hydrofluoric Acid

Given the ways it is used, it's no surprise that Hydrofluoric Acid is an extremely dangerous chemical that must be handled with the utmost care. A proper chemical storage system is absolutely necessary for your facility.

A corrosive liquid, hydrofluoric acid penetrates tissue more quickly than typical acids. Toxicity can occur through dermal, ocular, inhalation, and oral routes. Since it alters nerve function, accidental exposure can go unnoticed by the victim, delaying treatment and increasing the extent of injury. It can also be absorbed by the blood through the skin, reacting with blood calcium and potentially causing a heart attack.

The extreme nature of this chemical calls for superior structural integrity—the type of chemical tank system integrity that Poly Processing is known for.

Learn how to properly store other corrosive chemicals in polyethylene tanks.

The Poly Processing Hydrofluoric Acid System

When people’s lives are at risk, you can’t take any chances. You need a storage system that goes above and beyond to prevent contact with the chemicals, reduce leak opportunities, and is designed and engineered to be safe for the chemical stored in the tank.

That system starts with a high-density cross-linked polyethylene (XLPE) tank. XLPE is a thermoset resin that gives customers 20 times the environmental stress-crack resistance, 10 times the molecular weight, and greater impact and tensile strength compared to high-density linear polyethylene (HDPE). Our XLPE tank even carries a full five year warranty.

When working in close quarters, or looking to ensure containment, a SAFE-Tank can help reduce health and environmental concerns due to it being a closed containment system. If a SAFE-Tank is not a possibility, or a necessity, a Vertical or Slope-Bottom IMFO® (Integrally Molded Flanged Outlet®) tank can reduce hands-on maintenance, thereby reducing the risk to your employees.

SAFE-Tank® System

Because of its hazardous and highly corrosive nature, it is important to have a double wall containment system for hydrofluoric acid. Poly Processing’s SAFE-Tank system is a “tank within a tank” that provides greater safety by offering secondary containment that is completely enclosed. The SAFE-Tank provides 110 percent containment within the same footprint as a vertical storage tank, making it easy to store the chemical wherever it’s most efficient and convenient.

IMFO® Tank

If you have containment already in place, consider using the full-drain IMFO Tank. Poly Processing’s Integrally Molded Flanged Outlet (IMFO) Tank uses a flange system that is molded as part of the tank during manufacturing, making the flange a stress-free part of the tank. The flange is created from the same material as the tank — it’s not an insert added during or post-production.

Some companies create tanks out of one substance and insert a metallic flange post-production, for drainage and discharge. This saves money on tooling, but it creates opportunities for leaks to occur.

Advantages of the IMFO Tank include:

- Full tank discharge — Because the flange is at the bottom of the sidewall, below the tank knuckle radius. There’s no need to enter the tank for cleaning.

- Highest amount of static head pressure — The IMFO’s design brings you the highest net positive suction head (NPSH) of any vertical non-coned tank on the market.

- Enhanced long-term performance — Get a fuller useful life out of the tank, since the flange doesn’t compromise the tank’s hoop integrity or structural design.

- Complete flange face protection — The antioxidant OR-1000™ system can protect the discharge components from deterioration, even with aggressive oxidizing chemicals.

- Hassle-free maintenance — Unlike metallic inserts, the flange extends away from the tank wall and the entire flange system is external with easy access.

Store the Harshest Chemicals with Confidence

Storing hydrofluoric acid properly is critically important. At Poly Processing, we are committed to providing comprehensive storage solutions for Hydrofluoric Acid from <30% to 70% concentration and other potentially harmful chemicals as well.

Hydrofluoric Acid is an NSF/ANSI 61 approved chemical at 52% concentration or less for Poly Processing's tank systems. The tank system is a 1.9 spg. XLPE tank, Polypropylene Fittings, Viton Gaskets, and C-276 bolts.

To get more information on properly storing hydrofluoric acid, download our storage guide.

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Caustic Soda Storage Challenges and Solutions

- Scrubbing a PPC Tank: An Introduction to Fume Scrubbers

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package