The Latest Advances in Removing PFAS from Water

PFAS continues to make headlines and cause concern because these compounds have been detected in drinking water supplies across the country. The Agency for Toxic Substances and Disease Registry has determined that PFAS accumulation in the human body can have adverse health effects. In response, to provide Americans, including the most sensitive populations, with a margin of protection from a lifetime of exposure to PFOA and PFOS from drinking water, U.S. Environmental Protection Agency (EPA) has established the health advisory levels at 70 parts per trillion. In addition, the EPA has set a drinking water lifetime health advisory limit of 70 parts per trillion (ppt) for PFOA and PFOS. These are some of the lowest limits ever established for a contaminant.

PFAS are also very challenging to remove from water and wastewater. Treatment facilities and environmental engineering firms are busy developing viable treatment methods. We spoke with Katie Wolohan, an environmental engineer at Barr Engineering, to learn about how Barr is addressing this issue.

You can listen to the full interview or read the summary below. Click on the title in the player below to download or the play button to listen.

What are PFAS?

Per- and polyfluoroalkyl substances (PFAS) also known as perfluorinated chemicals or PFCs, are synthetic, man-made chemicals that include more than 4,000 individual compounds. They are commonly found in liquid dispersions or formulated mixtures and serve many useful functions across a variety of industries.

PFAS are used to coat non-stick cookware, waterproof and stain-resistant surfaces, and in products like Teflon™ and Gore-Tex™, among several other consumer products. They are also used in aqueous film-forming foam (AFFF) or fire-fighting foam to create a barrier between a fire and the oxygen source. PFAS are used in the automotive, construction, electronics, aerospace industries, and more.

PFAS are considered emerging contaminants, which means some studies have shown that these chemicals pose risks to human health and the environment; however, toxicologists are still learning more about the long-term health effects.

How do PFAS get into our drinking water?

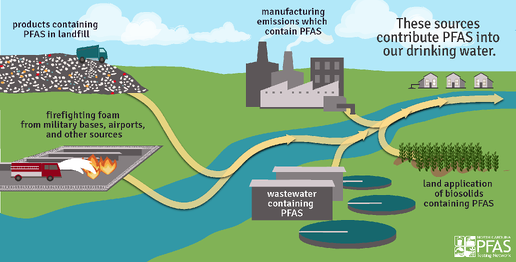

There are multiple ways that PFAS can enter drinking water supplies. They can travel from the ground surface through the unsaturated soil zone from a spill, a disposal site, or from the use of AFFF. PFAS can also enter groundwater through air deposition, where airborne PFAS travels some distance before landing on the ground and over time, will eventually make it to the groundwater table with precipitation.

These substances are also found in landfill leachate. In a lined landfill, leachate is typically discharged to a wastewater treatment facility. These compounds are generally not removed by conventional wastewater treatment, meaning they remain in both biosolids and treated wastewater. PFAS can leach into groundwater through land-applied biosolids.

Additionally, treated wastewater is often discharged to a surface water, which may be a drinking water supply or interact with groundwater. Because these chemicals do not degrade in the environment, PFAS mass is moved from one source to another and eventually reports to water.

Why are PFAS challenging to treat?

PFAS are environmentally persistent. They do not break down or biodegrade and tend to attach to organic carbon in soils, becoming a continuous source of groundwater and surface water contamination. PFAS are also not removed or destroyed by common water treatment methods and technologies.

The carbon-fluorine bond is the strongest bond in nature and very difficult to break, which means there are limited options for PFAS water treatment. Adsorption processes are most commonly used at this time. Through these methods, PFAS are adsorbed onto some type of media, such as granular activated carbon or ion exchange resin that eventually requires incineration to destroy the compounds.

Some experimental technologies are currently being tested on bench and pilot scales, such as electrocoagulation and plasma reactions, among other onsite destruction options. Due to the level of development, these technologies may not be viable options for PFAS water treatment for some time, and they will likely be best suited for small volume water and wastewater treatment only.

What is currently available to treat water?

The most well-understood and studied method of PFAS water treatment granular activated carbon (GAC) adsorption. Water enters a pressure vessel system that typically consists of lead and lag vessels filled with GAC where PFAS adsorbs within the carbon pores until a specific amount of adsorption capacity is used up and the carbon is considered spent. Spent GAC removed from the vessels is disposed of, reactivated, or sent to an incinerator for complete PFAS destruction.

Another widely used PFAS treatment method is ion exchange media adsorption, both single-pass and regenerable. Ion exchange works by trading an inert ion, such as chloride, for PFAS at the surface of the resin in a lead-lag vessel system.

Ion exchange resin on a per pound or cubic foot basis is more expensive than GAC, however, ion exchange requires a shorter empty-bed contact time, which refers to the time that water is in contact with the media. This usually results in a smaller volume of media for PFAS adsorption and lower-cost, smaller-footprint systems.

Other treatment options include membrane treatment, including nanofiltration and reverse osmosis. These technologies are effective in removing PFAS from water to an extent but are not employed as frequently as granular activated carbon and ion exchange because of significant capital and operations and maintenance costs. Additionally, membrane treatment produces a reject or concentrate stream, where PFAS are concentrated into a smaller volume that requires further treatment or incineration, which is challenging and expensive.

For smaller systems, how are chemical storage tanks used in treatment?

Barr Engineering has a client with a difficult-to-treat, small-volume wastewater stream that has historically been discharged to the local sanitary sewer. Last year, the client proactively sought to treat PFAS from their wastewater to be able to continue discharging to the sanitary sewer. Barr designed a batch treatment process that removes solids and other contaminants from the wastewater prior to PFAS media adsorption.

Poly Processing Slope-bottom tanks are used for untreated and treated wastewater equalization, and cone-bottom reactor tanks are used in the pretreatment process, where solids are separated from the wastewater through a chemical precipitation process.

Our unique sloped bottom tank system greatly minimizes the hazards associated with traditional vertical tank maintenance. With Poly Processing’s Sloped Bottom Integrally Molded Flanged Outlet tank, or IMFO® system, the flange is molded at the bottom sidewall while the tank is processing, making it a stress-free part of the tank. The floor of the tank is sloped towards the IMFO giving the user the greatest possible full discharge system in a vertical tank design.

Flanged Outlet tank, or IMFO® system, the flange is molded at the bottom sidewall while the tank is processing, making it a stress-free part of the tank. The floor of the tank is sloped towards the IMFO giving the user the greatest possible full discharge system in a vertical tank design.

How can someone contact Barr Engineering?

You can visit their website to learn about all of their service offerings including their PFAS services. You can also contact Katie directly.

- November 1, 2021

- Topics: Applications

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package