Safe Aluminum Sulfate Storage

Aluminum sulfate, also known as cake alum or papermaker’s alum, is a flocculant chemical, much like ferric.

One of the things that separates aluminum sulfate from other flocculants is that it works well for municipal wastewater treatment, lake treatments, and restoration. It's also used to make water safe for drinking.

Popular Uses of Aluminum Sulfate

Aluminum sulfate is used to remove organic compounds from wastewater and potable water. The chemical encourages small particles to cling to larger particles in water. When those large particles are filtered out, much of the aluminum sulfate goes with it. While aluminum sulfate can't remove pathogens or bacteria, the coagulation process reduces the presence of dissolved substances in water, which means less chlorine is needed for disinfection.

Aluminum sulfate is used to remove organic compounds from wastewater and potable water. The chemical encourages small particles to cling to larger particles in water. When those large particles are filtered out, much of the aluminum sulfate goes with it. While aluminum sulfate can't remove pathogens or bacteria, the coagulation process reduces the presence of dissolved substances in water, which means less chlorine is needed for disinfection.

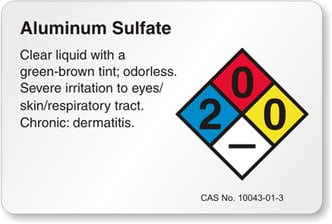

Aluminum sulfate can be harmful to humans, causing severe burns if it touches bare skin and irritation and coughing if inhaled. Because of the nature of this chemical, a specialized storage solution is best for maximum safety.

Why Proper Storage is Important

Here are a few reasons why aluminum sulfate requires specialized storage:

- Aluminum sulfate can separate, causing pumping problems.

- Delivery of the chemicals at elevated temperatures -- especially during the colder months -- can cause expansion and put stress on a storage tank.

- Chemicals like aluminum sulfate can create vapor or fumes which can cause damage to surrounding trees and plants.

- Coagulation, settling and separation can all cause storage problems, especially in concert with temperature variations.

A proper storage solution can preserve the integrity of the product and maintain safety:

- Poly Processing's high-density cross-linked (XLPE) storage tank handles expansion and contraction due to elevated temperatures and reduces the risk of tank failure. A chemical tank for aluminum sulfate should have a specific gravity rating of 1.65.

- On the bottom sidewall of the tank, consider a full-drain IMFO fitting. This fitting is molded into the tank at lowest point possible on the sidewall which helps with total drainage and potential leaks with mechanically attached fittings.

- Components of your tank should include PVC fittings, 316 SS bolts, and EDPM gaskets.

- Heat pads and insulation help regulate temperature, reducing the chance of separation.

- Mixers help prevent the aluminum sulfate from separating.

For additional information, you can download the Ferrics, Alums, and Polymers Guide.

If you have specific questions about storing aluminum sulfate, contact a Poly Processing chemical storage tank expert today.

- February 7, 2017

- Topics: Chemicals

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package