Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

Effective wastewater treatment relies on three essential pillars:

- Physical processes (screening and filtration)

- Biological treatment (oxidation ponds and lagoons)

- Chemical applications

Unlike municipal drinking water treatment, wastewater processing demands more intensive chemical use at higher volumes - making safe, compliant chemical storage absolutely critical.

The wastewater treatment cycle encompasses five fundamental stages: solid particle removal, neutralization, odor control, disinfection, and sludge treatment, and removal. This guide focuses on the crucial final stage: sludge removal and the specialized chemicals that make it possible.

Understanding the Importance of Sludge Removal

Wastewater sludge is composed of the concentrated solid material remaining after treatment - a mixture of bacteria, organic matter, and particles extracted during the purification process.

Effective sludge removal serves two critical purposes: preventing the accumulation of potentially hazardous materials and maintaining optimal wastewater system performance. Modern facilities employ several proven removal methods, including:

- Gravity thickening: Using natural gravitational forces within large tanks or basins to separate sludge from water

- Aerated stabilization: Introducing controlled air flow to accelerate sludge breakdown and enhance stability

- Centrifugation: High-speed spinning technology that efficiently separates sludge from liquid

Sludge Characteristics Across Treatment Systems

Both on-site systems (septic tanks) and off-site facilities (activated sludge plants) generate sludge as an inevitable byproduct of solid waste removal. Sludge composition varies dramatically, from fresh fecal material with high pathogen concentrations to decomposed matter aged over months or years, where natural die-off has significantly reduced pathogen levels. Treatment protocols must be tailored to these specific characteristics.

Prior to final disposal, sludge undergoes treatment to reduce volume and stabilize organic content. Properly stabilized sludge is odor-free and safe to handle, while volume reduction translates directly to lower costs for storage, pumping, and disposal operations.

Modern Sludge Treatment Technologies

Today's treatment facilities can choose from multiple processing options: stabilization, thickening, dewatering, drying, and incineration. Among these, dewatering—typically using polymer chemicals—offers cost-effective volume reduction.

Dewatering can reduce sludge liquid volume by up to 90 percent. These processes can use industrial centrifuges that function similarly to washing machine spin cycles. Centrifugal force separates water from solids, creating biosolid material, while extracted water returns to the plant for reprocessing. Filter presses are also used to dewater sludge as well.

Polymer addition enhances consistency, producing a firmer, more manageable biosolid cake — ideal for handling and disposal.

Important Safety Note: Polymers create slippery surfaces, presenting slip and fall hazards when spills or leaks occur. These chemicals can also act as environmental stress crack agents, requiring careful material selection for storage containers.

Optimal Storage Solutions for Sludge Removal Polymers

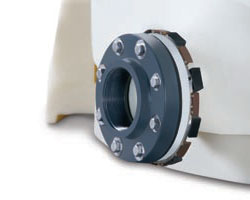

The gold standard for polymer storage is a cross-linked polyethylene vertical tank with sloped bottom design featuring an IMFO® (Integrally Molded Flanged Outlet) system. This configuration delivers effortless maintenance with true bottom-of-sidewall drainage and discharge capabilities.

Poly Processing’s IMFO Tank provides superior benefits to wastewater treatment facilities. No other chemical storage tank on the market offers the convenience, protection, and discharge advantages on an IMFO. Key benefits include:

- Complete drainage/discharge: Flange positioning below the tank knuckle radius enables full discharge without tank entry for cleaning

- Enhanced durability: Preserves tank hoop integrity and structural design for extended service life

- Chemical resistance: The antioxidant OR-1000™ system protects discharge components in aggressive oxidation environments

- Superior hydraulic performance: Delivers the highest net positive suction head (NPSH) available in vertical non-coned tanks

- Simplified maintenance: External flange system with accessible hardware eliminates the challenges of metallic inserts

- Universal compatibility: If your chemical is safe in cross-linked polyethylene tanks, it's safe with the IMFO system

Cross-linked polyethylene construction accommodates thermal expansion and contraction while maintaining structural integrity, significantly reducing failure risk. Supplementary heat pads and insulation maintain optimal chemical temperatures, preventing separation and settling. Integrated mixing systems offer additional protection against chemical separation.

Partner With Chemical Storage Experts

If your facility uses chemicals for wastewater sludge removal, we provide comprehensive solutions tailored to your storage requirements. Contact us today to discuss your specific needs.

- February 9, 2026

- Topics: Applications

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package