Be Sure Your Ferrous Chloride Storage Tanks Are Up to the Task

Odor control is an essential priority for all wastewater treatment plants. Hydrogen sulfide forms in wastewater and creates a strong odor that can be detected in water, and even in surrounding neighborhoods near the treatment plants.

Wastewater odors develop in the treatment plant’s collection system, sedimentation basins and sludge handling areas. As biological activity creates an anaerobic condition, fumes are released as sulfides are formed.

The odors are noxious, and as public awareness grows, wastewater treatment plants face increasing pressure to reduce or eliminate the offensive odors.

Using Liquid Ferrous Chloride for Wastewater Solutions

Liquid ferrous chloride is one of the main chemicals used for wastewater odor control. In many cases treatment plants vent through an odor scrubber that has the ferrous chloride in it to remove the hydrogen sulfide.

Liquid ferrous chloride is one of the main chemicals used for wastewater odor control. In many cases treatment plants vent through an odor scrubber that has the ferrous chloride in it to remove the hydrogen sulfide.

Other uses of ferrous chloride include:

- Precipitating and removing phosphates

- Eliminating sulfide-based odors

- Reducing arsenic and mercury

- Reducing hexavalent chrome

- Controlling struvite

- Adjusting pH

Liquid ferrous chloride is a concentrated solution of iron II chloride (FeCl2) in water. It’s a free-flowing liquid that can remain stable for indefinite periods. Ferrous chloride is also used to dechlorinate water before discharging effluent.

There are several reasons why ferrous chloride requires specialized storage:

- Separation, settling and coagulation are major issues with this chemical – and those conditions can be compounded by temperature variations.

- Settling and separation issues can lead to difficulty in pumping the chemical.

- The chemicals are often delivered at elevated temperatures, testing the expansion and contraction capabilities of a tank.

- Ferrics create fumes that can defoliate surrounding trees and plants.

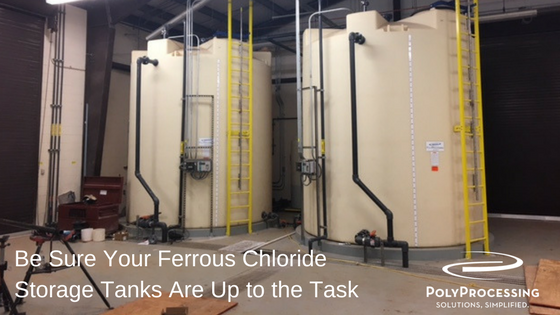

Properly Storing Ferrous Chloride

Ferrous chloride is a hazardous substance that must be handled and stored properly. It is a highly corrosive chemical that can irritate and burn the eyes and skin. Breathing the chemical can irritate the nose and throat, and repeated exposure may cause nausea and gastrointestinal damage.

Providing the right kind of storage is essential in order to maintain personal, property, and environmental safety – and to maintain the integrity of the product. Cross-linked polyethylene tanks resist chemical corrosion and offers superior durability. We submit our cross-linked polyethylene tanks to five rigorous quality assurance tests to ensure that you get unmatched chemical storage performance.

For more information on storing ferrous chloride, download our Ferrics, Alums & Polymers Guide.

- April 27, 2017

- Topics: Chemicals

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

- Why Chemical Storage Tank Wall Thickness Matters and How to Get It Right

- The Best of 2025 - Top 5 Chemical Storage Blogs

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package