Industrial Hydrochloric Acid Uses & Storage Concerns

Hydrochloric acid (HCl), also known as muriatic acid, is toxic and highly corrosive. The chemical is used in many different applications, including chloride production, refining ore, and producing metals like tantalum and tin.

Because HCl is such a powerful acid, it is often used for neutralizing basic solutions. It also requires careful handling and an engineered storage system that is designed specifically for hydrochloric acid.

Hydrochloric Acid In Nature

Interestingly enough, HCl can be found in the human stomach. It's part of our gastric acid and forms an important part of our digestive system. Although it is quite damaging, the stomach is protected from damage by a secretion of a thick layer of mucus as well as a hormone called secretin. In some cases, people might suffer from indigestion or even a stomach ulcer if this acid is not handled properly by the built-in mechanisms of the body.

This is not the only place we find it working, it has a variety of uses across multiple industries.

What is Hydrochloric Acid Used For?

Hydrochloric acid is integral to several industrial applications. Some of the most common hydrochloric acid uses include:

-

- Manufacturing organic compounds like dichloroethane and vinyl chloride, which are used to manufacture PVC (poly vinyl chloride).

- Regulating the pH level of a wide variety of manufacturing processes, including the production of drinking water, foods, and pharmaceuticals.

- Lowering the pH or total alkalinity of the water in swimming pools to optimal levels for swimmers.

- Purifying table salt.

- Pickling steel — removing rust and scale from a steel coil or sheet.

- Processing leathers in the leather tanning industry.

- Regenerating ion exchangers.

- Producing inorganic compounds such as ferric acid and aluminum chlorohydrate for water treatment.

- Assisting oil well production.

- Processing various additives like fructose, citric acid, and hydrolyzed vegetable protein.

The Right Storage System for Hydrochloric Acid

Poly Processing offers a complete chemical storage system for every industry that uses hydrochloric acid. Because correct storage methods are critical, we offer several storage tank configurations to meet your specific needs.

It's important to ensure that your hydrochloric acid storage solution meets the correct set of standards for your specific application. Poly Processing is committed to the highest standards and we are the only company with a complete chemical tank system certified to NSF/ANSI 61 standards. NSF/ANSI 61 relates to water treatment as well as the stringent requirements that control equipment used in water products and potable water.

Because HCl is highly corrosive, we recommend specific tank safeguards. In the event of a chemical spill, secondary containment is critical for preventing damage to equipment and protecting your employees.

Our SAFE-Tank® system is a double-wall tank that completely contains a spill if the primary tank becomes compromised. This tank-within-a-tank design is ideal for safely containing hydrochloric acid in the event of a chemical spill.

Looking for more information about building the right chemical storage system? Check out our comprehensive tank buying guide.

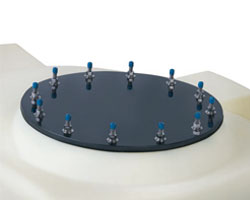

Tank Fittings for HCl

The tank isn’t your only concern in storing hydrochloric acid. Metal tank fittings are susceptible to corrosion as well, and leaks can form at joint fittings. Our slope-bottom IMFO® tank features an integrated outlet that provides full drainage without exposure to metal fittings.

The unique sloped bottom minimizes the hazards associated with maintaining a traditional vertical tank—especially one that stores HCl.

Scrubbing Hydrochloric Acid Fumes

Your chemical storage system isn’t complete without a chemical fume scrubber to prevent fumes from venting into the atmosphere. Hydrochloric acid produces toxic hydrogen chloride gas that can corrode equipment and cause long-term bodily harm. Improper scrubbing can create a false sense of security, putting your people in jeopardy.

Poly Processing offers scrubbers for our hydrochloric acid tank systems. Automated scrubbers continually monitor the pH of the scrubbing media and automatically change out the media when the pH becomes too low or too high.

It’s very important to properly size your fume scrubbers, based on the size of your chemical tank. We’ve seen companies design their own scrubbing system, and it often backfires. Poly Processing Company only supplies chemical fume scrubbers with our tank systems. We can help you determine your scrubber requirements. Contact Poly Processing to design your tank system and fume scrubbers.

To find out more about the storage of hydrochloric acid in a Poly Processing Tank — Download our Hydrochloric Acid Position Statement.

- May 20, 2024

- Topics: Chemical Storage

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package