Poly Processing’s IMFO and Sloped Bottom IMFO - Which is Right For You?

One of the biggest challenges in chemical storage tank design is achieving a full drain of the chemicals from the tank during regular operation as well as cleaning.

Constraints on space, the incorrect placement of fittings, or dealing with hazardous chemicals can all create issues for chemical evacuation. That's why Poly Processing Company has developed the IMFO and Sloped-Bottom IMFO tanks.

Let’s look at the main differences between these two systems and how those differences might enhance your specific applications.

IMFO Provides Full Drain

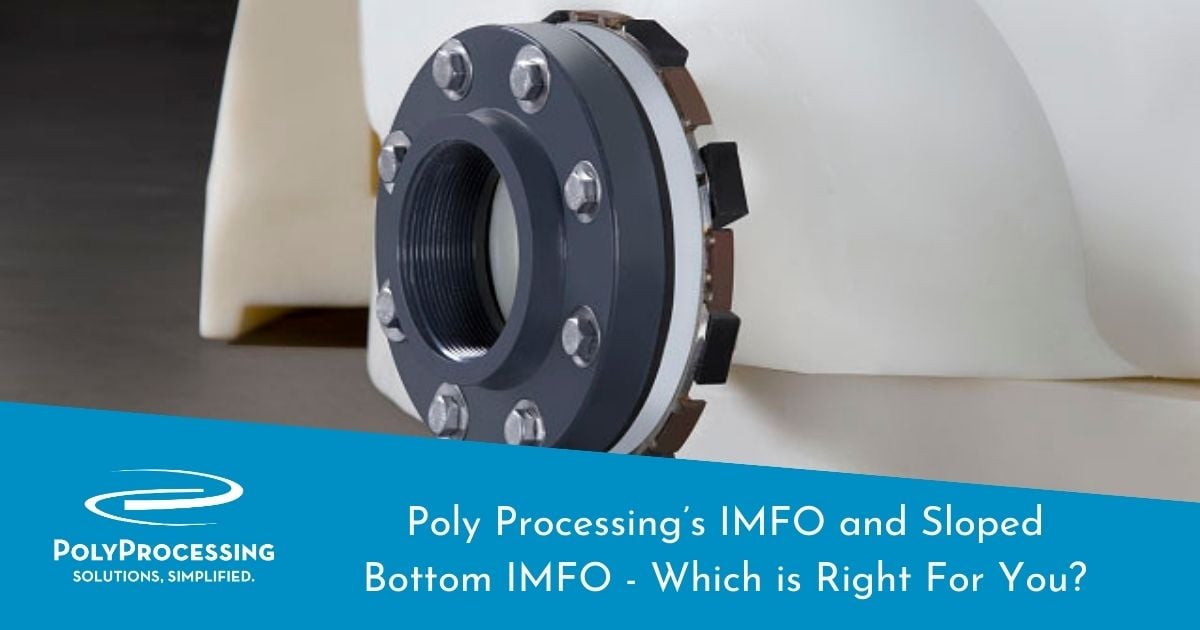

A chemical storage tank with an Integrally Molded Flanged Outlet (or IMFO fitting), provides a full drain because of the way it is manufactured - the flange is at the lowest point of the sidewall of the tank and is molded as part of the tank when it is made so that the lowest portion sits below the bottom knuckle radius. This specialized design eliminates the need to enter the tank or a confined- space entry for cleaning.

A chemical storage tank with an Integrally Molded Flanged Outlet (or IMFO fitting), provides a full drain because of the way it is manufactured - the flange is at the lowest point of the sidewall of the tank and is molded as part of the tank when it is made so that the lowest portion sits below the bottom knuckle radius. This specialized design eliminates the need to enter the tank or a confined- space entry for cleaning.

In addition to being easier and safer to clean, the IMFO tank is also more reliable over time because the risk of compromise to the structural integrity of the tank sidewall is low due to the flange being molded as part of the tank and not added on later like some bulkhead fittings or metallic inserts.

Sloped IMFO Excels for Heavier Chemicals and Substances

Poly Processing also has a sloped-bottom version of the IMFO tank, which we recommend for heavier materials such as FOG (fat, oils, and grease), sludge, etc. The additional gravity feed allows for these heavier substances to drain more easily and that makes cleaning it even simpler because there’s no need for a confined-space entry. No one has to get in with a mop or pressure washer. Instead, it can be cleaned from the top from the manway, or with a spray ball installed in the dome, which is much safer for personnel.

Poly Processing also has a sloped-bottom version of the IMFO tank, which we recommend for heavier materials such as FOG (fat, oils, and grease), sludge, etc. The additional gravity feed allows for these heavier substances to drain more easily and that makes cleaning it even simpler because there’s no need for a confined-space entry. No one has to get in with a mop or pressure washer. Instead, it can be cleaned from the top from the manway, or with a spray ball installed in the dome, which is much safer for personnel.

Second, the sloped IMFO allows the heavier materials and chemicals to evacuate during draining so there is no sediment or sludge that builds up. The sloped IMFO has all of the features of the IMFO tank with the additional advantage of the slope.

Key Differences of the IMFO to Note

An IMFO tank, because of the flange, needs to sit on a raised flat pad. In most cases, a contractor will pour a concrete pad wide enough for the IMFO tank to sit on and provide a cutout for the IMFO fitting. (PPC can supply a plastic pad in some cases but in most instances we recommend using a structural concrete pad instead).

With the sloped IMFO, the bottom of the tank is sloped: If you put a sloped IMFO tank on a flat pad, it will lean. Therefore a sloped IMFO tanks needs a pad where the concrete is poured based on its specific tank slope design. This allows it to sit flat and secure and allows standard seismic systems to be installed.

There are also differences between the size options: IMFO tanks range from 200 gallons to 15,500 gallons while sloped IMFO tanks have a smaller range, from 3,950 gallons to 15,000 gallons. So, depending on your chemical storage gallonage needs, one tank may be prefered over another.

To learn more about polyethylene chemical storage tanks with an IMFO or sloped IMFO fitting, contact Poly Processing today.

- April 14, 2016

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Caustic Soda Storage Challenges and Solutions

- Scrubbing a PPC Tank: An Introduction to Fume Scrubbers

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package