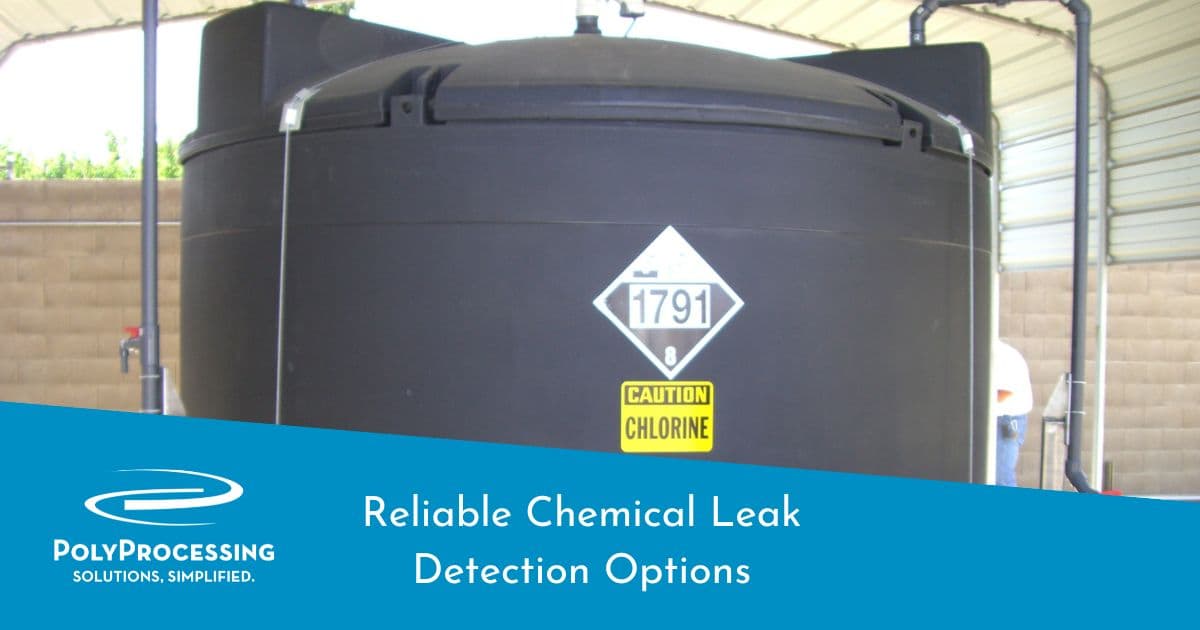

Reliable Chemical Leak Detection Options

Chemical leaks present several major challenges for your facility. They can cause damage to storage systems, employees, and the environment. Repair and cleanup costs can be expensive, and the leaked chemical is wasted.

In extreme situations, the lack of a leak detection system can result in catastrophic events, like the chemical spill in the Elk River in West Virginia. In this article, we’ll look at leak detection systems for your chemical storage tanks.

Chemical Leaks Are Inevitable

If you’re storing corrosive chemicals, your chemical storage tank will eventually leak, given enough time. Our cross-linked polyethylene (XLPE) tanks have a useful life three times as long as other storage tanks—but even XLPE tanks don’t last forever.

Leaks can occur for other reasons, as well. Three common causes include:

- A loose or leaking fitting

- A broken pipe

- An overfilled tank caused by problems with the pump mechanism upon filling by the tanker truck

Our double-wall containment system, called SAFE-Tank®, safely contains any leaks, but you need to know when a leak has occurred. Because the SAFE-Tank is completely enclosed, a leak detection sensor will immediately alert you to a chemical leak when it first occurs. You can then investigate the problem and contact our Field Service Department to have the problem assessed.

How Does Chemical Leak Detection Work?

Sensors are installed in the Poly Processing double-wall tank in one of two ways. They can be dropped down into the interstitial space between the primary and secondary tanks, or they can be installed in a fitting through the containment tank at the bottom.

The alarm alerts workers that liquid is escaping from the primary tank into the containment area. Depending on your preferences, you can use an audible alarm sound or a flashing light at the tank, or send the alert through a SCADA system into a control room.

By using a SAFE-Tank chemical storage tank, you’re ensuring that any chemical leak is detected by sensors, thus keeping containment intact. This means that your employees, your facility, and the environment are all still safe from harm and you can continue operations until a Field Service expert can address the issue. By not having to immediately shut down operations, you’re saving time and money for the plant and the employees.

Types of Leak Detection

In Poly Processing’s polyethylene SAFE-Tank, either an optical or ultrasonic leak detector can be used to detect leaks in the secondary containment tank. Both leak detection methods are equally effective.

With the optical leak detector, an infrared beam is calibrated to pinpoint the bottom surface of the secondary containment tank. If chemicals have leaked into the secondary containment an alarm is triggered.

With the ultrasonic leak detection, a sound beam is sent to the base of the secondary polyethylene containment tank. If the beam distance is shorter, it indicates a substance at the bottom of the tank, and an alarm is sent to the system.

Leak Detection for Your Storage Tanks

While not all municipalities and local codes require leak detection on chemical storage tanks, many customers choose to place these devices in their tanks for safety and productivity purposes. If you’re storing dangerous chemicals, you may be required to have leak detection. Make sure you know whether or not leak detection is needed.

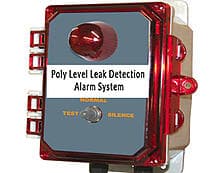

Poly Level Leak Detection Alarm System

The Poly Level Leak Detection Alarm System is an excellent choice for leak detection in double-wall or secondary containment tanks. It features:

- High Intensity Red Alarm Light

- 90 dB Audible Alarm with External Test-Silence-Normal Positions

- Rugged NEMA 4X Industrial Design Enclosure

- Latching Lockable Cover (No Screws Required) Lockable

- External Mounting Feet Installs in Minutes

- UL Listed Enclosure (CSA)

- High Impact All Plastic Polycarbonate Shell

- Small Foot Print – Compact Design

- Excellent Chemical Resistance

- Includes 6′ Power Cord + Seal-Tight Cord Connector

Download our info sheet and drawing.

Poly Level Leak Detection Sensor

The Poly Level Leak Detection (PLLD) Industrial Series is an advanced all-plastic corrosion resistant leak detection liquid level sensor. The device uses ultra-sensitive electrostatic technology, which constantly and accurately senses the presence of liquids. These sensors are Ideally suited for monitoring the interstitial area between double wall tanks, tank retention walls, secondary containment sumps, and areas where process pumps and valves are utilized.

The PLLD sensor has been engineered to withstand even the most extreme conditions while including features designed to optimize performance and reduce maintenance.

- Suitable for Corrosive Environments

- High Stability with Thermal Compensation

- PP All Plastic Body

- Non-Contact Technology

Download our info sheet and drawing.

Learn more about incorporating proper leak detection for your chemical storage system. Contact our chemical storage experts today!

Learn more about incorporating proper leak detection for your chemical storage system. Contact our chemical storage experts today!

- January 30, 2023

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Caustic Soda Storage Challenges and Solutions

- Scrubbing a PPC Tank: An Introduction to Fume Scrubbers

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package