Use a Desiccant Dryer System to Keep Moisture Out of Your Tank

Bulk stored chemicals can become contaminated from two major sources: debris and moisture. As the product is emptied from the chemical storage tank, dirty air and moisture can be drawn into the tank. Temperature fluctuations can also cause the tank to expand and contract, so that it “breathes” contaminants in and out.

Maintaining chemical purity is essential in many industrial chemical applications, such as computer chip manufacturing, food processing, clean in place, and pharmaceutical manufacturing. Contaminated chemicals can become less effective, and more hazardous to your storage equipment.

To prevent contamination, Poly Processing often recommends installing special accessories. Tank vent dryers and desiccant filters may be your best choice for keeping moisture out of the chemical storage tank.

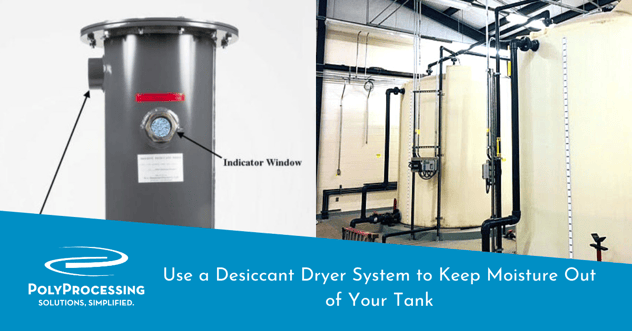

We are proud to introduce a desiccant dryer system. This desiccant dryer system can be added to almost any tank size or any tank type that Poly Processing Company manufactures. It comes in two sizes: 2-inch (fits nearly every application) and 3-inch.

The gypsum media powder inside the dryer can be replaced periodically or regenerated with heat from an oven. An indicator window on the dryer changes color when the media needs to be replaced or regenerated.

Tank vent dryers can be especially valuable if you’re storing sulfuric acid. Because concentrated sulfuric acid is hygroscopic, any moisture entering the tank will be quickly absorbed into the chemical. If your supply of sulfuric acid isn’t frequently replenished, the top layer of acid can become more diluted, and more corrosive. As the contents continue to sit in the tank, the top layer of weak acid often will corrode a ring around the inner tank wall.

Let’s take a closer look at the role of desiccant dryer systems.

What’s the Difference Between a Desiccant Dryer and a Tank Vent?

A desiccant dryer adsorbs the water vapor onto the large, dry surface area of a highly porous material called desiccant. This adsorption occurs as water vapor in the compressed air moves into the pores of the dry desiccant and is attracted to the surface of the pores.

A desiccant dryer system is a small accessory placed inline with the vent. While a vent and desiccant dryer are similar, the two accessories have important differences:

- A standard vent lets air with moisture enter the tank, which can decrease the effectiveness of some chemicals.

- Saving on repeated chemical costs (from shortened effective life) easily justifies the price of the system.

- A desiccant dryer requires a larger vent (6 in required), which also increases overall tank life.

Tank Vent Dryer Design Considerations

Desiccant dryers are the most common way of keeping moisture out of a tank. The size of the dryer is determined by the amount of air and the rate at which the air enters the storage tank. Generally, this is the pump-out rate, although a large tank that is nearly empty can have an air intake that’s faster than the pump-out rate.

The desiccant that is used in the dryer should be sized to last from one to six months per charge of desiccant.

Poly Processing can help engineer the best option to meet your specific challenges. Let us help you maintain proper air flow, venting, and filtering to prevent chemical contamination with a specialized vent design.

Contact a Poly Processing storage tank specialist today to learn more.

- April 5, 2021

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package