Storing Oxidizing Chemicals? Extend the Life of Your Tank

Sodium hypochlorite is a chemical used in thousands of applications. As an aggressive oxidizer, it’s critical to limit the opportunity for the chemical to escape the storage tank. If you’re using a polyethylene tank to store oxidizing chemicals, you can multiply the useful life of your chemical storage tank by using an engineered polyethylene antioxidant tank system.

The Challenge of Storing Corrosive Chemicals

A corrosive chemical like sodium hypochlorite will damage or destroy another substance upon contact. It can cause chemical burns to living tissue. Fumes from the chemical can cause eye and lung irritation or damage. Some commonly stored corrosive chemicals are:

Many of these oxidizing chemicals can corrode metal, especially at higher temperatures. When metals corrode because of these substances, they produce a flammable hydrogen gas. Steel chemical tanks pose a risk of oxidation, but that risk is eliminated with crosslinked polyethylene (XLPE) tanks.

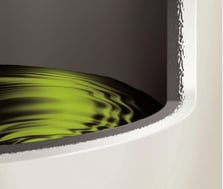

Antioxidants and the Importance of OR-1000™

When storing oxidizing chemicals like sodium hypochlorite, peracetic acid, etc. engineered antioxidant systems provide greater useful life for the interior tank wall. Most polyethylene resin already contains some form of antioxidants, but the antioxidants are exhausted during the manufacturing process. Because they’re being oxidized during curing of the poly tank, the antioxidants are spent by the end of the process and are no longer able to provide protection. We add a secondary antioxidant system to protect against oxidizing chemicals and extend the life of the tank. Poly Processing’s OR-1000 System adds an antioxidant barrier between the oxidizing chemical and the high-density crosslinked polyethylene. The OR-1000 system is specifically formulated to resist oxidation and give the user greater tank life. The outer surface is made of XLPE and offers superior strength, longevity, and chemical resistivity. The two surfaces are molecularly bound together during the roto-molding process, creating a truly seamless bond between the XLPE and the inner surface of the polyethylene tank.

Poly Processing’s OR-1000 System adds an antioxidant barrier between the oxidizing chemical and the high-density crosslinked polyethylene. The OR-1000 system is specifically formulated to resist oxidation and give the user greater tank life. The outer surface is made of XLPE and offers superior strength, longevity, and chemical resistivity. The two surfaces are molecularly bound together during the roto-molding process, creating a truly seamless bond between the XLPE and the inner surface of the polyethylene tank.

OR-1000 system addresses the chemical resistance of oxidizing chemicals for 15+ years. The OR-1000 system is not your typical resin. In fact, it has four times the antioxidizing power, compared to other commercially-available resins. This high level of antioxidant additive ensures greater longevity for your tank.

Latest Resin Technology

Recently, with the help of a third-party leader in Polymer Engineering, we developed a new and improved OR-1000 resin. We've taken what we’ve learned in the field in the last 30 years and improved the material.This new resin carries other enhancements, including:

- Improvements in the long-term properties: The enhanced resin will last longer and allow your tank to last longer, too.

- High levels of ESCR: High levels of ESCR (Environmental Stress Crack Resistance) even when storing chemicals such as sodium hypochlorite or peracetic acid

- Improved elongation: the new OR-1000 will maintain its elongation properties over time while storing heavy oxidizing chemicals. This performance is superior to the previous OR-1000 and other HDPE materials commonly used in tank construction.

Uncompromising Chemical Tank Longevity

With the OR-1000 system, you can extend the life of your XLPE tank when storing highly oxidizing chemicals. The technology behind OR-1000 takes the guesswork out of choosing the right storage tank system for oxidizing chemicals. This antioxidant resin, combined with XLPE, creates a stronger, more durable tank without the risks and maintenance costs of an FRP tank or a high-density polyethylene tank.

The combination of polyethylenes creates an ideal tank system for the most corrosive and oxidizing chemicals. The value, longevity, strength and durability of the OR-1000 system can handle almost any chemical and stand the test of time.

For more information on using XLPE and OR-1000 to store corrosive chemicals, download the OR-1000™ Guide.

- February 10, 2020

- Topics: Tank Design and Materials

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

- Why Chemical Storage Tank Wall Thickness Matters and How to Get It Right

- The Best of 2025 - Top 5 Chemical Storage Blogs

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package