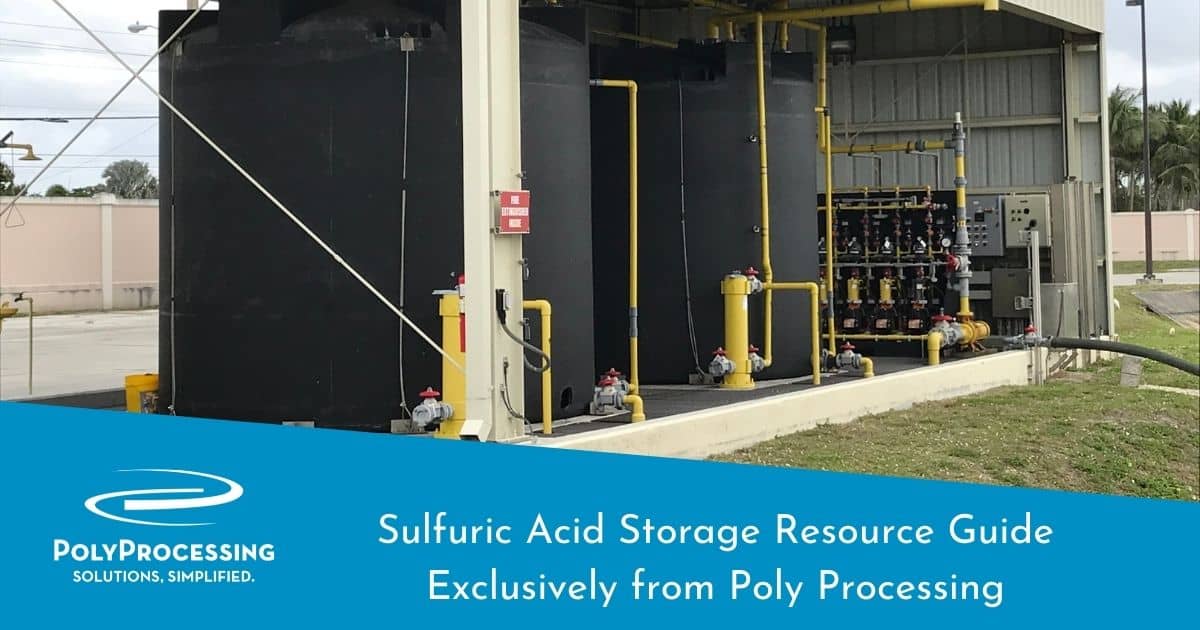

Sulfuric Acid Storage Resource Guide Exclusively from Poly Processing

Sulfuric acid can be a tricky chemical to store. Used in a wide variety of industrial applications, sulfuric acid is heavy, can create toxic or flammable gas, and can burn the skin. A smart storage solution for sulfuric acid should start with a well-thought-out tank design — not just the tank material but the entire storage system and all its components.

Thinking through the entire sulfuric acid tank system design up front will help you protect your employees, the environment, and your investment. Read on for our recommendations on the right material, configuration, and standards for safe sulfuric acid storage.

What Do You Need To Know About Sulfuric Acid?

Sulfuric acid is a strong and highly corrosive mineral acid with the molecular formula H2SO4. It is a pungent-ethereal, colorless-to-slightly yellow viscous liquid which is soluble in water at all concentrations. Sometimes, it is dyed dark brown during production to alert people to its hazards. Concentrated sulfuric acid is 98% pure and shows different properties, depending upon its concentration — for instance, battery acid is 30% sulfuric acid.

Most sulfuric acid (~60%) is used for fertilizers, particularly superphosphates, ammonium phosphate and ammonium sulfates. About 20% is used in the chemical industry to produce detergents, synthetic resins, dyestuffs, pharmaceuticals, petroleum catalysts, insecticides and antifreeze. It’s also used in various processes such as oil well acidizing, aluminum reduction, paper sizing, and water treatment.

Because the hydration reaction of sulfuric acid is highly exothermic, dilution or contact with water must be performed carefully by personnel who are experienced in sulfuric acid safety.

Best Tank Material For Sulfuric Acid Storage

At Poly Processing, we’ve developed proprietary polyethylene as the ideal storage material for sulfuric acid. Crosslinked polyethylene (XLPE) tanks provide unmatched load tolerance that can more than handle the chemical’s heavy weight.

XLPE’s molecular bonding, combined with a thick tank wall, provides necessary structural strength. This is especially critical in the bottom third of the liquid storage tank, where the highest hoop stress levels are concentrated.

We’ve created a downloadable resource guide for sulfuric acid storage. This guide will walk you through essential storage solution considerations, including:

- Challenges of storing sulfuric acid

- Tank options: stainless steel, fiberglass, single-wall, and double-wall

- Important factors when choosing a storage solution

- Tank installation and maintenance

Tank Configuration For Storing Sulfuric Acid

Secondary containment is recommended when storing sulfuric acid. If your storage tank leaks, secondary containment can capture the leak before it causes a risk to your staff or facility.

If you don’t already have a secondary containment structure in place, our SAFE-Tank® solution is a smart choice. A SAFE-Tank is a tank-within-a-tank system that has secondary containment built-in. It is a space and cost-efficient method that greatly reduces the possibility of sulfuric acid leaking into the surrounding environment or coming into contact with water (which can result in a toxic sulfuric acid aerosol or a potential explosion).

Sulfuric Acid Storage Tank Size Recommendations

Sulfuric acid is a very heavy chemical which puts a lot of stress on a storage tank. Therefore, only a set amount can be safely stored in a single tank. When storing sulfuric acid in a Poly Processing tank, just remember the 11/15 rule. You can use any tank less than 11,000 gallons and less than 15 feet tall. This includes the Vertical, IMFO®, Sloped IMFO®, and SAFE-Tank Systems.

Other storage requirements for sulfuric acid vary, depending on the concentration of the chemical.

- Concentrations of 93-98 percent: Because the weight is up to 16 pounds per gallon, 93-98% concentrated sulfuric acid must be stored in a tank that has a 2.2 specific gravity wall thickness. The OR-1000® System with PVC fittings, Viton Gaskets, and 316 Stainless Steel bolts are also required for this concentration.

- Concentrations from 80 percent to less than 93 percent: Because this lower concentration of sulfuric acid can be corrosive to stainless steel, alloy C-276 bolts with Viton gaskets and PVC fittings are required along with a 2.2 specific gravity tank and the industry-leading OR-1000 System.

- Concentrations of less than 80 percent: A 2.2 SPG tank with the OR-1000 System. The fittings required are PVC, with Viton gaskets and alloy C-276 bolts.

- Tank recommendations for concentrations of 98 percent or less: Poly Processing's double-walled SAFE-Tank with the OR-1000 system is necessary if no secondary containment is available. If containment is provided, a full-discharge Vertical IMFO tank or Sloped Bottom IMFO tank are excellent choices.

In all cases, the OR-1000 antioxidant system must be used. The OR-1000 system is designed to provide longer useful life by helping to reduce the oxidation of the polyethylene tank system.

NSF-61 Certifications For Sulfuric Acid Storage

Poly Processing chemical tanks are certified to NSF/ANSI-61 Standards, up to a 98% concentration of sulfuric acid. Poly Processing is the only company with a complete chemical storage tank system certified to NSF/ANSI Standard 61. All Poly Processing, OR-1000 chemical storage tank systems and associated fittings adhere to these stringent specifications.

Environmental Science and Engineering Magazine

In April 2022, Environmental Science and Engineering magazine published an article on Sulfuric Acid Storage. You can download the article here.

For more information, download our Sulfuric Acid Resource Guide.

- June 12, 2023

- Topics: Chemicals, Chemical Storage

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package