Maximizing Fill Efficiency: Selecting the Optimal Fill Line System

Proper tank filling operations directly impact your facility's safety record, product loss rates, and operational efficiency. The right fill line system does more than simply moving chemicals from delivery trucks to storage tanks. It also minimizes spill risks, protects personnel, and can significantly reduce filling time while preventing costly product waste.

.jpg?width=1200&height=630&name=Maximizing%20Fill%20Efficiency%20Selecting%20the%20Optimal%20Fill%20Line%20System%20(2).jpg)

Fill Line System Components and Design

Modern fill line assemblies use engineered piping systems—predominantly PVC or CPVC construction for broad chemical resistance. These piping systems are integrated directly with your storage tank. They typically incorporate ball valves for positive shut-off control and quick-disconnect camlock fittings that prevent inadvertent chemical release during connection changes.

Modern fill line assemblies use engineered piping systems—predominantly PVC or CPVC construction for broad chemical resistance. These piping systems are integrated directly with your storage tank. They typically incorporate ball valves for positive shut-off control and quick-disconnect camlock fittings that prevent inadvertent chemical release during connection changes.

Available configurations include internal drop pipes, external routing systems, hybrid combination designs, and specialized anti-foam assemblies. Each configuration addresses specific operational challenges while improving overall filling performance. This article introduces you to each of these fill line assemblies.

Internal Drop Pipe Systems: Controlled Delivery Performance

Internal fill systems position the delivery pipe inside your tank. They connect through a top-mounted fitting, commonly a bulkhead fitting or universal ball dome style. The drop pipe extends to within a few inches of the tank floor, although this dimension can be customized based on your specific requirements.

The internal drop pipe configuration delivers several operational benefits. By positioning chemical delivery near the tank bottom, internal systems virtually eliminate splashback and foam generation during filling operations. If you attach a pump, the same piping can function as a tank drain system, reducing the need for additional bottom outlet fittings and minimizing potential leak points in your system.

Read: Better and Safer Alternatives to Downpipes

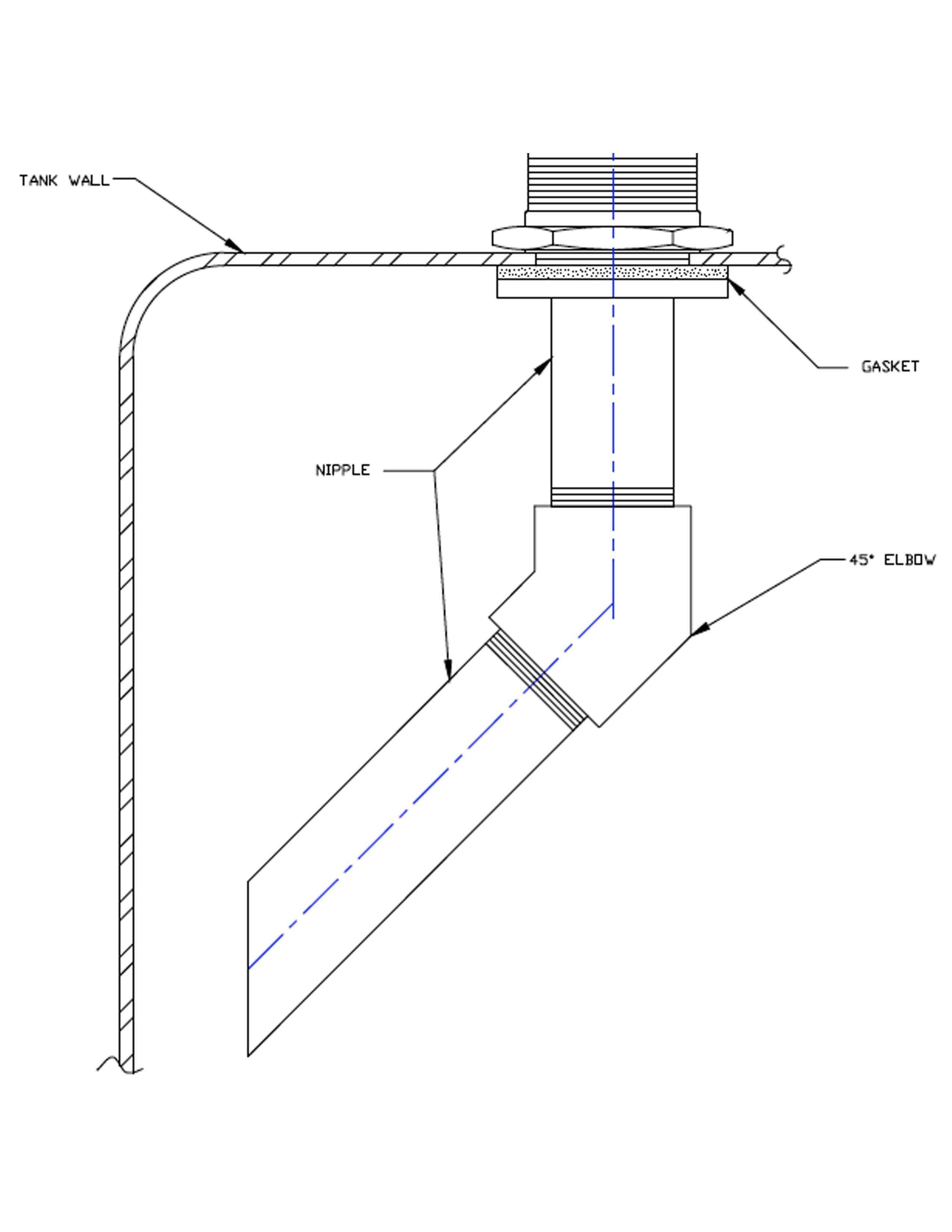

Anti-Foam Elbow Assemblies: Addressing Hydraulic Issues

Internal drop pipes can create operational challenges with certain types of chemicals. High-density fluids delivered under pneumatic pressure may cause hydraulic shock when compressed air becomes trapped beneath the liquid surface, encountering substantial head pressure from existing tank contents.

Anti-foam elbows solve this problem through smart design. These compact assemblies mount at the tank top and redirect incoming chemical flow along the tank sidewall at a 45-degree angle. This uses the same principle as pouring a carbonated beverage into a glass to minimize foaming.

Elbow assemblies prevent hydraulic shock by allowing trapped air to escape at the elbow opening, rather than becoming pressurized below the liquid surface. Anti-foam elbows also offer cost advantages due to their simplified construction compared to full internal piping systems.

External Routing Systems: Enhanced Operational Flexibility

External fill line configurations mount piping outside the tank structure, connecting to top-mounted fittings through external routing. Proper pipe support brackets ensure system stability and prevent stress loading on tank connections.

External fill line configurations mount piping outside the tank structure, connecting to top-mounted fittings through external routing. Proper pipe support brackets ensure system stability and prevent stress loading on tank connections.

External systems excel in operational versatility. Camlock connections enable rapid truck hookups, while external piping can be routed throughout your facility to position fill connections in optimal locations. This brings outdoor delivery access to indoor tanks or routing connections across facilities for improved accessibility and workflow efficiency.

IMPORTANT: If you use multiple fill lines on multiple tanks, it is critical to label each one at the filling point to avoid putting the wrong chemical in the wrong tank.

Hybrid Combination Configurations: Comprehensive Performance

Combination fill systems integrate external routing flexibility with internal drop pipe performance. External piping provides versatile connection options while an internal drop tube extending near the tank bottom minimizes turbulence and foam generation during filling.

Combination fill systems integrate external routing flexibility with internal drop pipe performance. External piping provides versatile connection options while an internal drop tube extending near the tank bottom minimizes turbulence and foam generation during filling.

These systems require both internal and external support structures, but they deliver optimal performance for critical applications where filling speed, foam control, and operational flexibility are all essential requirements.

System Selection and Installation Considerations

Your optimal fill line configuration depends on multiple factors: chemical properties, facility layout, delivery logistics, and operational priorities. Regardless of configuration choice, proper mounting and support systems are critical. Well-engineered support structures ensure your fill line maintains integrity and functionality even when subjected to accidental contact from delivery vehicles or facility equipment.

Investing in properly designed fill line systems delivers measurable returns through reduced spill incidents, faster filling cycles, improved personnel safety, and extended tank service life through gentler filling processes.

For more information about the proper fill line system for your facility, contact our tank design engineers today.

- December 1, 2025

- Topics: Fittings and Accessories

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

- Why Chemical Storage Tank Wall Thickness Matters and How to Get It Right

- The Best of 2025 - Top 5 Chemical Storage Blogs

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package