What’s New With Poly Processing’s OR-1000 Engineered Resin?

Recently, with the help of a 3rd party leader in Polymer Engineering, we developed an enhanced OR-1000 resin. We've taken what we’ve learned in the field in the last 15 years and improved the material.

Poly Processing’s exclusive OR-1000™ system was designed to address aggressive oxidation. We've recently developed a new enhanced version of the resin as an effective solution for your chemical storage needs.

Let's take a look at OR-1000, what it is, and what the new improvements are that we've made to the resin.

What is the OR-1000 system?

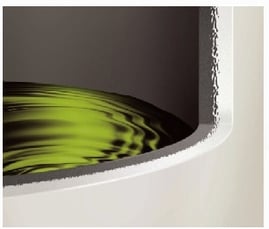

The OR-1000 system is an inner-surface engineered resin with four times the antioxidant power of a standard tank wall. The OR-1000 system is added at the end of the cooking cycle. After most of the structurally superior cross-linked resin has cured the tank to a near complete part, the OR-1000 system is added in what is referred to as the “double-shot”. The mold is stopped just long enough to inject the OR-1000 system resin into the XLPE, resulting in a seamless bond. The additional resin is added, bonded, and cured along with the partially cured inner surface of the XLPE.

The OR-1000 system is an inner-surface engineered resin with four times the antioxidant power of a standard tank wall. The OR-1000 system is added at the end of the cooking cycle. After most of the structurally superior cross-linked resin has cured the tank to a near complete part, the OR-1000 system is added in what is referred to as the “double-shot”. The mold is stopped just long enough to inject the OR-1000 system resin into the XLPE, resulting in a seamless bond. The additional resin is added, bonded, and cured along with the partially cured inner surface of the XLPE.

This process only takes a few minutes as the tank finishes so the antioxidants are “uncooked away”, in tact and fully charged for use on-site. It's used when storing oxidizing chemicals like sodium hypochlorite, sulfuric acid, and hydrochloric acid. The OR-1000 system adds an extra chemical barrier between cross-linked polyethylene (XLPE) and the chemical.An antioxidant barrier is all about extending the life expectancy of normal polyethylene

The OR-1000 system is a polyethylene resin containing saturated amounts of antioxidants. The engineered inner surface is made of polyethylene formulated to resist oxidation. The outer surface of the tank is made of XLPE for superior strength. These surfaces are molecularly bound together during the rotomolding process.

The Advantages of the OR-1000 system

The OR-1000 system gives you four times the antioxidant resistance of any polyethylene you can find. All wetted surfaces are covered by OR-1000, eliminating the chance for chemical attack on the tank's structure.

The OR-1000 system can also be used on any PPC tank, including the SAFE-Tank and vertical tank with IMFO system.

Improved OR-1000 Resin Offers Many Benefits

Recently, with the help of a 3rd party leader in Polymer Engineering, we developed a new OR-1000 system. We've taken what we’ve learned in the field in the last 15 years and improved the material.

Still NSF certified and FDA compliant, this new resin carries other enhancements, including:

- Improvements in the long-term properties: The enhanced resin will last longer and allow your tank to last longer, too.

- High levels of ESCR: High levels of ESCR (Environmental Stress Crack Resistance) in the presence of Sodium Hypochlorite

- Improved Elongation: The new OR-1000 system will maintain its elongation properties over time while in the presence of heavy oxidizing chemicals. This performance is superior to the previous OR-1000 system and other HDPE materials commonly used in tank construction.

If you’re storing an oxidizing chemical, the OR-1000 system antioxidant additives help ensure polyethylene tank longevity. And now with an improved resin, OR-1000 is even more beneficial.

If you’re storing an oxidizing chemical, the OR-1000 system antioxidant additives help ensure polyethylene tank longevity. And now with an improved resin, OR-1000 is even more beneficial.

For more information on our improved OR-1000 system, contact Poly Processing today.

- May 25, 2016

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package