Getting Your Plastic Tank Foundation Right: Why Professional Design Matters

When installing a plastic storage tank, whether for water, chemicals, or other liquids, the foundation pad might seem like a simple concrete slab. However, proper pad design is critical for tank performance, longevity, and safety – and it's more complex than you might think.

Why Tank Pad Design Matters

A poorly designed foundation can lead to serious problems:

- Tank failure from uneven settling or stress concentration

- Costly repairs or complete tank replacement

- Environmental contamination from leaks or ruptures

- Safety hazards for personnel and surrounding areas

- Regulatory violations and potential fines

Key Design Considerations

Professional engineers evaluate multiple factors when designing tank pads:

Load Distribution: The pad must evenly distribute the tank's weight (including contents) across the soil beneath the tank, preventing settlement or tilting.

Size Requirements: The pad needs to extend beyond the tank base to provide adequate support and prevent edge loading.

Thickness Calculations: Pad thickness depends on tank size, contents, soil conditions, and local building codes.

Soil Analysis: Understanding soil bearing capacity and potential for settlement is crucial for long-term stability.

Drainage: Proper grading and drainage prevent water accumulation that could undermine the foundation.

Environmental Factors: Climate, seismic activity, and local conditions all influence design requirements.

Don't Go It Alone

While it might be tempting to estimate pad requirements or copy another installation, every situation is unique. Soil conditions, tank specifications, contents, and local codes vary significantly between projects.

A qualified structural engineer will:

- Analyze your specific site conditions

- Calculate appropriate pad dimensions and reinforcement

- Ensure compliance with local building codes

- Provide stamped drawings for permit approval

- Help prevent costly mistakes and safety issues

Don’t Use Dirt or Asphalt Foundations

It’s important not to use a dirt, gravel, or asphalt foundation for your chemical storage tanks. Some customers have tried to use this kind of foundation for their tanks, and it usually fails. While packed dirt, asphalt, or gravel seem like solid foundations that can also save time and money, they actually create a dangerous scenario that can compromise the integrity of your chemical storage system.

Over time, rain erodes the dirt and shifts the rocks underneath the storage tank. Even when using asphalt, the base can settle unevenly under the weight of a full chemical tank. This causes uneven stress on the tank, which can compromise the integrity of the sidewall.

In the event of a leak, the leaked chemical will go directly into the soil, creating an environmental contamination that can introduce legal action and heavy fines.

In addition, seismic and wind restraints require a concrete pad. They aren’t compatible with a dirt foundation.

Concrete Pad Design with Seismic Systems

Customers often ask how to design and pour their pad to accommodate the tank and a seismic system. Poly Processing has a set of standards that can help the engineer, contractor, or the end user to design and build the correct pad for the tank. The pad size depends on both the tank size and the type of seismic restraint system you will be installing. Seismic calculations and design should be provided by Poly Processing and a third-party engineer for any PPC tank needing seismic systems or wind restraints.

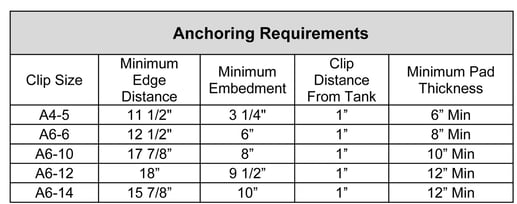

Below is a PPC-created table which showcases some of the standards for pad design. This table is based on locations with Ss=1.700 and S1=0.750 values or less.

- Minimum Edge Distance – The distance from the sidewall of the tank to the edge of the pad.

- All concrete pads with seismic systems or wind restraints need a 28-day compressive strength of 2500 psi. minimum or as directed by American Concrete Institute (ACI) 318-11.

Note: Anchoring requirements can be modified per specific site and tank size as required to meet your specific needs. Please feel free to contact customer support for any clarification you might need.

Concrete Pads For IMFO Tanks One of Poly Processing’s innovative tank system is the Integrally Molded Flanged Outlet® (IMFO®) Tank that minimizes the hazards associated with traditional vertical tank draining and maintenance. With Poly’s IMFO system, the flange is molded at the bottom knuckle radius while the tank is processing, making it a stress-free part of the tank. The flange therefore sits below the bottom of the tank to create this full drain feature.

We require that the pad be notched where the IMFO will sit so that the pad will not interfere with the fitting assembly. You can view IMFO design drawings that show the different pad shapes and how the IMFO area should be notched.

Poly Processing has been supplying seismic calculations and systems for our tanks for over 40 years. We recommend contacting a storage tank system expert for your individual seismic restraint needs.

The Bottom Line

Investing in professional engineering design upfront is far less expensive than dealing with foundation problems later. Your tank represents a significant investment – protect it with a properly engineered foundation.

Before you pour that concrete, consult with a licensed engineer. Always check local building codes and regulations, as requirements vary by location and application. Your tank, your budget, and your peace of mind will thank you.

- October 27, 2025

- Topics: Tank Design and Materials

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package