Polyethylene Resin: How Resin Testing Led to Chemical Storage Innovation

Twenty years ago, the availability of commercial grade cross-linked polyethylene (XLPE) for chemical storage tanks was limited to a small number of sources. The limited supply, as well as a wide variation in quality, made it challenging to find quality resin for chemical storage tanks.

To control manufacturing quality and create a steady supply source, Poly Processing led the charge in developing a robust, high-density crosslinked polyethylene (XLPE) that could be used with great success in chemical storage vessels — both large and small.

Innovating Better Cross-Linked Polyethylene Solutions

The quest to develop an industry-leading XLPE resin began in 2003. In conjunction with the Pennsylvania College of Technology, the process consisted of developing a variety of resins, as well as rigorous short-term and long-term testing.

Once a number of resin compound variations were developed, they were subjected to impact, hoop stress, environmental stress crack, tensile strength, and several other tests in the lab. This lab work produced new resin compounds that were ready for testing in the field.

In order to get an idea of how these new resins would perform in real-world scenarios, we manufactured test tanks with the new resin compounds. Numerous resin variations were field-tested over several years with fertilizer applications in agriculture.

In these tests, the tanks were not only required to successfully contain the chemical being stored, they were also subjected to the demands of frequent movement.

We also recruited partners to test and monitor the performance of these tanks in controlled storage situations. The tanks were placed under various chemical applications and conditions to verify the longevity and performance of each tank.

The result of this extensive testing and development is a XLPE resin custom-tailored for large, thick-walled chemical storage tanks. It’s a robust, long-lasting material that meets strict quality specifications.

Read more: Discover the latest innovations in chemical storage

What Makes Cross-Linked Polyethylene Unique?

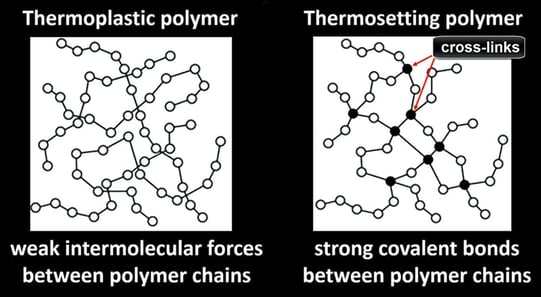

Crosslinking is simply the formation of bonds between the polymer chains. These bonds are equal in strength and stability to the principal bonds along the polymer backbone. During the crosslinking process, the bonds tie the polymers together, thus dramatically increasing molecular weight.

As a result, the length of the polymer chains, and the physical properties, are much better than can ever be achieved without crosslinking.

The result is a plastic that possesses impact resistance, tensile strength, and resistance to fracture that linear polyethylene just can’t match. These qualities make cross-linked polyethylene an excellent choice when tank integrity is critical. The structural integrity, heat resistance, and useful life are unparalleled.

Strength and Durability: Linear Vs. Cross-Linked Polyethylene

Both linear and cross-linked polyethylene resins are rotational molding-grade resins that have been ground into a powder to allow the material to melt easily during the molding process. Both types of resins are available in standard colors as well as some custom colors. Both resins are corrosion-resistant polyethylene.

However, the differences are critical. Compared to linear polyethylene, XLPE provides:

- 10 - 20 times the environmental stress crack resistance

- 10 times the molecular weight

- 3-5 times the impact and tensile strength

The four most important factors of high-density linear tanks and cross-linked tanks include:

- Environmental stress crack resistance/notch sensitivity

- Long-term hydrostatic strength

- Toughness and Durability

- Useful Life

In all four of these areas, testing and measurements show cross-linked resins are more durable than linear resins.

The Poly Processing Tank Drop Test Method

Three drop tests were performed, using 3,000-gallon tanks. The first test consisted of two tanks, one made from crosslinked polyethylene and the other from linear polyethylene. The rotomolded tanks were fabricated in accordance with the instructions and guidelines highlighted in ASTM D1998-15. This ensured that these tanks met the quality requirements of optimum cure and proper fabrication.

In each test, the tanks were filled with water and dropped onto a concrete surface from a crane.

Drop Test 1

Each tank in the first set was filled with 7,000 pounds of water and lifted by crane 15 feet in the air. The tank was released to free-fall onto a concrete surface below. While the linear tank catastrophically failed, the crosslinked polyethylene tank didn’t fail or develop any cracks.

If you look closely at the linear polyethylene tank, you can see that the impact created a crack that quickly unzipped as the tank finished impacting the ground. This unzipping is a characteristic found in linear polyethylene resin grades.

Drop Test 2

After the first drop, we filled the exact same Poly Processing crosslinked tank with 11,000 pounds of water (more than 15 times the weight of an empty tank). The tank was dropped from the same height, to the same surface with no damage to the tank.

Drop Test 3

Finally, the same tank was dropped from the full height of the crane — 45 feet in the air — onto the concrete surface. Even after the third drop, containing 11,000 pounds of water, the tank remained 100 percent intact with no leaks or cracks.

For more information about Poly Processing’s tank testing process, contact a chemical storage system specialist.

- September 9, 2024

- Topics: Value Added

About Poly Processing

Posts By Topic

Tech Talk Podcast Episodes

Subscribe By Email

Recent Posts

- Ferric Chloride Storage: What Operators Need to Know Before Choosing a Tank

- Wastewater Treatment: Modern Approaches to Sludge Removal & Chemical Management

- Why Cycling Causes Tank Failure: Tips for Prolonging Tank Life

- Small Changes in Tank Selection for Big Long-Term Cost Benefits

- NSF Certification vs. FDA Compliance: Understanding Chemical Tank Standards

Tank Configurator

Find the recommended tank and system components for your chemical storage challenge.

Configure a Tank Package